Introduction

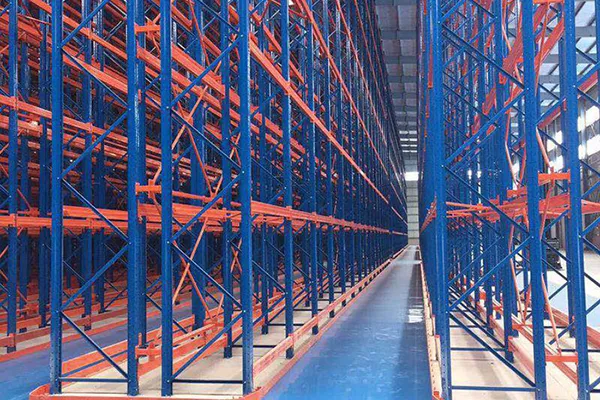

In the relentless pursuit of supply chain excellence, warehouse managers and operations leaders face a constant challenge: maximizing space without compromising efficiency. Traditional storage solutions often force a difficult trade-off, leaving valuable cubic airspace underutilized and creating operational bottlenecks. However, a revolutionary approach has reshaped the landscape of modern warehousing: VNA Racking. As a cornerstone of high-density storage systems, VNA Racking, or Very Narrow Aisle racking, is not merely an equipment upgrade but a strategic re-imagining of warehouse layout and workflow. This innovative system empowers businesses to dramatically increase storage capacity within the same footprint, slash operational costs, and build a more resilient, responsive, and future-proof logistics operation. This guide will delve into how VNA racking solutions are unlocking unprecedented potential for organizations worldwide.

Deconstructing the Design: Core Structural Characteristics

The unparalleled efficiency of VNA storage systems stems from its fundamental engineering and design principles. Unlike conventional wide-aisle racking, it is built for precision and vertical optimization.

- Ultra-Narrow Aisle Configuration: The most defining feature is the drastic reduction in aisle width. While standard systems require aisles of 3 meters or more to accommodate a counterbalance forklift, VNA racking systems operate effectively in aisles as narrow as 1.6 meters. This single change is the primary driver behind the significant increase in storage density.

- Guided Vehicle Operation: To navigate these tight spaces safely and precisely, VNA racking relies on specialized guided aisle trucks. These vehicles use either guide rails embedded in the floor or wire-guidance systems to travel with millimeter accuracy, eliminating the risk of collision with the racking structure.

- Robust Structural Integrity: To support the immense heights and heavy loads, the racking frames and beams are engineered for superior strength. These systems are often custom-designed to handle specific load requirements and can reach heights of over 15 meters, fully utilizing the building’s vertical clearance.

- Integrated Safety Systems: Safety is paramount in such a constrained environment. The design often includes base plates, row spacers, and structural bracing for enhanced stability, along with integrated safety barriers and sensors on the forklifts.

The Compelling Advantages

Implementing a high-density VNA storage system translates into a host of tangible benefits that directly impact the bottom line.

- Radical Space Optimization:

-

- Increase storage capacity by up to 50% or more compared to traditional systems.

- Transform wasted vertical space into profitable storage real estate.

- Free up floor space for other value-added activities like cross-docking or value-added services.

- Supercharged Operational Efficiency:

-

- Drastically reduce travel time for forklifts by shortening pick paths.

- Achieve faster order picking cycles and improve overall throughput.

- Enable seamless integration with Warehouse Management Systems (WMS) for optimized put-away and retrieval tasks.

- Uncompromising Safety and Accuracy:

-

- The guided navigation minimizes human error, virtually eliminating product and racking damage from collisions.

- Enhance operator safety with features like slow-down and stop sensors.

- Improve inventory accuracy by creating a more organized and controlled storage environment.

- Significant Cost Reduction:

-

- Reduce real estate costs by storing more in a smaller area or delaying the need for a costly facility expansion.

- Lower energy consumption and operational costs through more efficient material handling routes.

Key Applications and Industries

The flexibility of VNA pallet racking makes it suitable for a wide range of sectors where space is at a premium and inventory turnover is critical.

- Cold Storage Facilities: In these exceptionally expensive environments, maximizing every cubic foot is crucial. VNA racking solutions drastically reduce the refrigerated footprint needed, leading to massive energy savings and lower operating costs.

- Manufacturing and Raw Material Storage: Manufacturers can store a greater volume of raw materials and components closer to production lines, supporting Just-in-Time (JIT) processes and minimizing internal logistics time.

- Third-Party Logistics (3PL) and Distribution Centers: 3PLs handling diverse product portfolios for multiple clients benefit from the high density and excellent organization, allowing them to scale operations within a fixed building envelope.

- E-commerce Fulfillment Centers: The fast-paced, high-SKU nature of e-commerce requires rapid access to a vast array of products. VNA systems, when combined with the right software, can significantly speed up the picking process for high-volume operations.

Technical Specifications: Load and Configuration

A successful VNA racking installation hinges on precise technical planning tailored to your specific operational needs.

- Impressive Load-Bearing Capacity: A common question is, “how much weight can VNA racking hold?” These systems are designed for heavy-duty use. Static load capacities per pallet position can easily range from 500 kg to over 2,000 kg, accommodating a wide variety of goods from consumer products to heavy industrial materials. Dynamic capacities for the guided forklifts are equally robust.

- Customizable Configurations: Not all VNA racking systems are identical. They can be configured in multiple ways:

-

- Standard VNA for single-deep pallet storage.

- Double-Deep VNA, which sacrifices some selectivity for even greater density.

- Mobile VNA systems, where the entire racking structure is mounted on carriages that move, eliminating the need for multiple aisles entirely.

Steps to Implement VNA Racking Warehouse

Adopting this technology requires careful consideration. A phased approach ensures a smooth transition and maximizes return on investment.

- Phase 1: In-Depth Facility Assessment. This involves a professional analysis of your building’s dimensions, floor flatness, column spacing, and ceiling height to determine feasibility.

- Phase 2: Comprehensive System Design. Experts will design the layout, specify the racking, and select the appropriate guided vehicles based on your SKU profile and throughput requirements.

- Phase 3: Professional Installation and Integration. Skilled technicians install the system, ensuring it is perfectly leveled and secure, and integrate it with your existing WMS.

- Phase 4: Thorough Operator Training. Certified trainers ensure your forklift operators are proficient and safe in the new narrow-aisle environment.

Conclusion

The decision to invest in VNA Racking is a strategic move towards building a fundamentally smarter and more profitable logistics operation. It is a direct response to the growing pressures of rising real estate costs, complex supply chains, and rising customer expectations. By embracing the high-density, high-efficiency paradigm of VNA racking solutions, businesses are not just adding more shelves; they are unlocking latent capacity, boosting productivity, and future-proofing their supply chain. In the race for competitive advantage, the space you save and the efficiency you gain are the ultimate prizes.