In the dynamic landscape of modern warehouses and distribution centers, efficiency, space optimization, and seamless workflow are paramount. The integration of stacker crane with shuttle racking system has emerged as a game-changer, offering a sophisticated solution to these challenges. This innovative combination not only enhances operational efficiency but also ensures precise inventory management, making it a cornerstone of contemporary material handling technology.

Understanding the System: Stacker Cranes with Shuttle Racks

Stacker Cranes: The Workhorses of Vertical Storage

Stacker cranes, also known as automated storage and retrieval systems (AS/RS), are robotic devices designed to automate the storage and retrieval of goods in warehouses. These cranes operate within a defined storage area, typically a high-bay racking system, and are equipped with mechanisms to lift, move, and place loads with pinpoint accuracy. They can be categorized into several types, including single-masted, double-masted, and gantry cranes, each tailored to specific storage needs.

Shuttle Racks: The Backbone of High-Density Storage

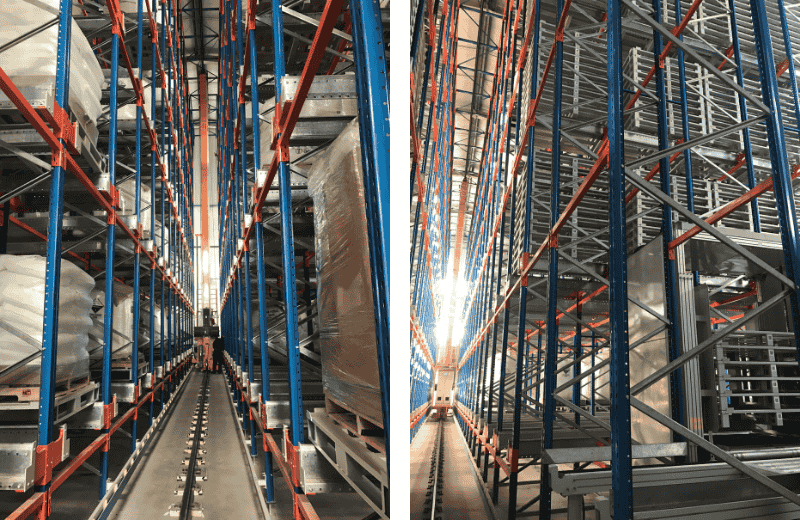

Shuttle rack systems represent a leap forward in high-density storage solutions. These systems utilize shuttle vehicles that travel along rails within the racking structure, autonomously transporting pallets or loads to designated storage locations. Shuttle racks are particularly advantageous in environments where space is at a premium, as they allow for multiple levels of storage without requiring additional floor space.

Key Features of the Stacker Crane with Shuttle Racking System

Automation and Efficiency

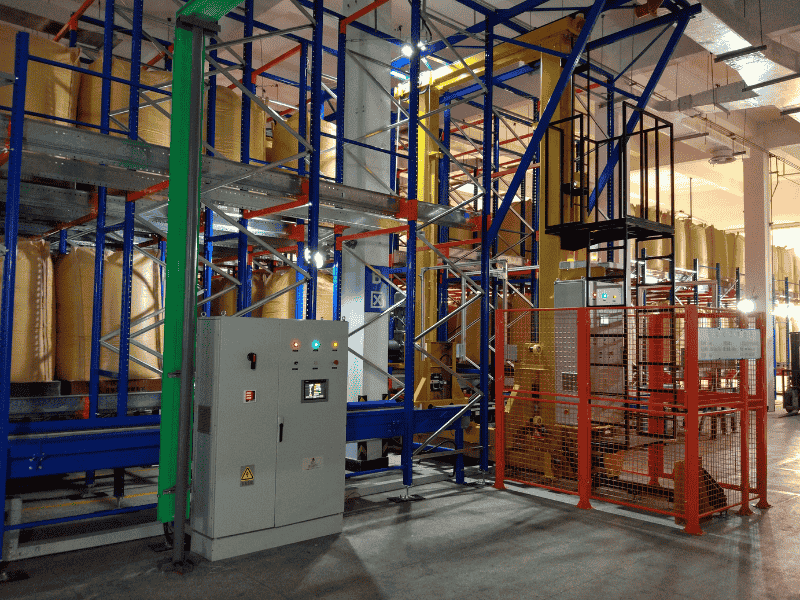

The primary advantage of this system is its automation capabilities. By eliminating the need for manual labor in inventory management, stacker crane with shuttle racking system significantly reduce operational costs and minimize human error. The system operates seamlessly, with stacker cranes retrieving items from shuttle racks and delivering them to designated picking stations, ensuring a continuous and efficient workflow.

Space Optimization

One of the most significant benefits of this system is its ability to maximize vertical space utilization. Shuttle racks allow for deep storage configurations, where multiple pallets are stored in a single lane, accessed by the shuttle vehicle. This approach minimizes the footprint of the storage area while increasing storage capacity, making it ideal for warehouses with limited space.

Flexibility and Scalability

The stacker crane with shuttle racking system is highly adaptable to various storage needs. It can be configured to accommodate different types of goods, including pallets, containers, and even irregularly shaped items. Additionally, the system can be scaled up or down based on the warehouse’s requirements, ensuring that it remains relevant as the business grows.

Safety and Reliability

Safety is a critical aspect of any material handling system, and the stacker crane-shuttle rack combination excels in this regard. Equipped with advanced sensors and control systems, these devices operate with precision, minimizing the risk of accidents. The system also features fail-safe mechanisms to prevent collisions and ensure smooth operation, even in high-traffic environments.

Technical Advantages

Advanced Control Systems

The integration of stacker crane with shuttle racking system is made possible by sophisticated control systems that manage the movement and coordination of these devices. These systems utilize real-time data processing and communication protocols to ensure seamless operation, allowing for precise inventory tracking and retrieval.

Energy Efficiency

Modern stacker cranes and shuttle vehicles are designed with energy efficiency in mind. They often feature regenerative braking systems, which convert kinetic energy back into electrical energy during deceleration, reducing overall power consumption. Additionally, the use of lightweight materials and optimized motor designs further enhance energy efficiency.

Integration with Warehouse Management Systems (WMS)

The stacker crane with shuttle rack system can be seamlessly integrated with warehouse management software, providing real-time visibility into inventory levels, order statuses, and operational metrics. This integration enables better decision-making, improved inventory accuracy, and enhanced overall warehouse performance.

Applications Across Industries

Manufacturing

In manufacturing facilities, the stacker crane with shuttle racking system is used to store raw materials, work-in-progress (WIP) items, and finished goods. The system’s ability to handle heavy loads and operate in confined spaces makes it ideal for environments where space is limited, and efficiency is critical.

Distribution Centers

Distribution centers benefit greatly from this system due to its high throughput and space-saving capabilities. By automating the storage and retrieval process, distribution centers can significantly reduce order fulfillment times, enhancing customer satisfaction and operational efficiency.

Cold Storage

The stacker crane with shuttle racking system is also well-suited for cold storage environments, where maintaining precise temperature control is essential. The system’s automation reduces the need for human intervention in cold storage areas, ensuring worker safety and preserving product integrity.

Retail and E-Commerce

In the retail and e-commerce sectors, where fast order fulfillment is crucial, the stacker crane-shuttle rack system enables efficient picking and packing operations. By automating these processes, retailers can meet the demands of online shopping while minimizing operational costs.

Product Benefits

Increased Throughput

The automation of the stacker cranewith shuttle racking system significantly increases the throughput of goods, allowing warehouses to handle larger volumes of inventory in less time. This is particularly beneficial during peak seasons when order volumes surge.

Reduced Labor Costs

By automating the storage and retrieval process, the system reduces the reliance on manual labor, leading to substantial cost savings. This is especially important in regions where labor costs are high, or skilled labor is scarce.

Enhanced Inventory Accuracy

The system’s integration with warehouse management software ensures that inventory levels are accurately tracked in real-time. This reduces the likelihood of stockouts and overstocking, improving overall inventory management and customer satisfaction.

Improved Safety

The stacker crane with shuttle racking system minimizes the risk of workplace accidents by reducing the need for workers to manually handle heavy loads or operate in hazardous environments. This not only enhances worker safety but also reduces the potential for costly workplace injuries.

Future Trends and Innovations

AI and Machine Learning Integration

The future of material handling lies in the integration of artificial intelligence (AI) and machine learning (ML) technologies. These advancements will enable stacker cranes and shuttle vehicles to predict demand patterns, optimize storage layouts, and even self-diagnose maintenance issues, further enhancing operational efficiency.

Autonomous Mobile Robots (AMRs)

The incorporation of autonomous mobile robots (AMRs) into the stacker crane & shuttle rack system is another emerging trend. AMRs can work alongside stacker cranes and shuttle vehicles, providing additional flexibility in material handling and further reducing reliance on manual labor.

Sustainability Initiatives

As environmental concerns grow, there is an increasing focus on sustainability in material handling technologies. Future iterations of the stacker crane & shuttle rack system will likely incorporate more eco-friendly materials, energy-efficient designs, and renewable energy sources to reduce their environmental footprint.

Conclusion

The stacker crane with shuttle rack system represents a transformative approach to material handling, offering unparalleled efficiency, space optimization, and operational flexibility. By leveraging advanced automation technologies, this system is reshaping the warehouse and distribution center landscape across various industries. As technology continues to evolve, we can expect further innovations that will enhance the capabilities of these systems, making them an indispensable component of modern logistics and supply chain management.