In the rapidly evolving logistics industry, where efficiency and precision are paramount, the integration of shuttle racking system with WMS (Warehouse Management Systems) has emerged as a game-changer. This advanced solution seamlessly combines automated storage technology with intelligent software, offering businesses a competitive edge in inventory management and order fulfillment. Whether you’re in e-commerce, manufacturing, or distribution, understanding this innovative duo can transform your operations.

Core Components of the Shuttle Racking System

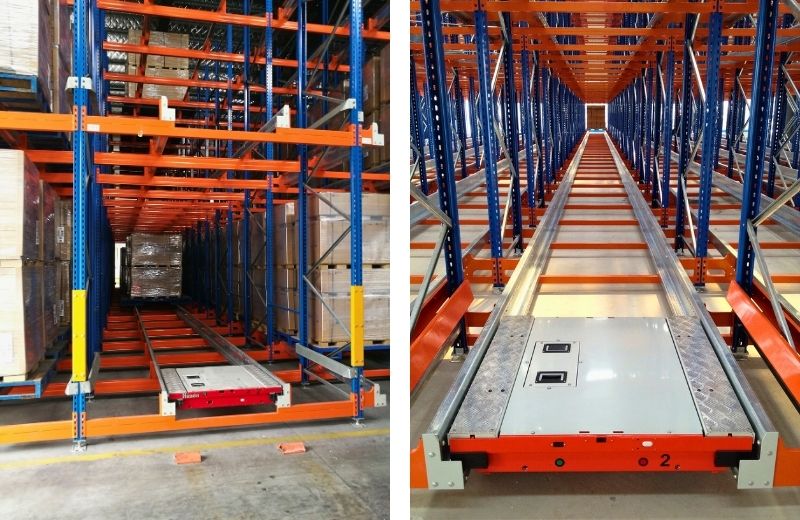

The shuttle racking system is a sophisticated assembly of hardware and software designed to optimize warehouse space and streamline material handling. At its heart lies the shuttle vehicle, a compact, battery-powered robot that moves along rails within the storage racking structure. These vehicles come in two primary types: single-shuttle systems, where one vehicle manages a single lane, and dual-shuttle systems, which employ two vehicles per lane for enhanced throughput.

Complementing the shuttle vehicles are the racking structures, typically constructed from high-strength steel to support heavy loads. These racks feature multiple levels and lanes, allowing for high-density storage. To facilitate seamless integration, the system includes RFID or barcode scanners for inventory tracking, sensors for position detection, and control panels for operator interface.

The WMS software acts as the brain of the operation, orchestrating the movement of goods, inventory updates, and order processing. It communicates with the shuttle vehicles via a Wireless Warehouse Control System (WCS), ensuring real-time synchronization between physical storage and digital records.

Key Functions and Operational Workflow

- Automated Storage and Retrieval

Upon receiving an order, the WMS calculates the optimal storage location based on factors like item popularity, expiration date, and order priority. It then instructs the shuttle vehicle to retrieve the item from the designated lane. The vehicle travels along the rail, picks up the item, and delivers it to a designated picking station or conveyor belt. This “goods-to-person” approach eliminates the need for workers to navigate aisles, significantly reducing picking time and errors.

- Dynamic Inventory Management

The WMS maintains a real-time inventory database, updating stock levels with each transaction. It can generate alerts for low stock, expired items, or potential overstock situations, enabling proactive replenishment. Advanced features like batch tracking and lot number management ensure traceability for industries with strict regulatory requirements.

- Order Consolidation and Batching

For high-volume order processing, the WMS groups multiple orders into batches based on destination, item type, or priority. It then optimizes the shuttle vehicle’s path to minimize travel time, improving overall warehouse efficiency. This batching capability is particularly beneficial for e-commerce fulfillment centers during peak seasons.

- Cross-Docking and Just-in-Time Delivery

In distribution centers, the shuttle racking system can support cross-docking operations, where incoming goods are directly transferred to outgoing vehicles without long-term storage. The WMS coordinates this process by synchronizing arrival and departure schedules, reducing handling costs and lead times.

Distinct Advantages of the Integrated System

Space Efficiency

By eliminating the need for wide aisles required by forklifts, the shuttle racking system achieves up to 85% higher storage density compared to conventional shelving. This vertical utilization of space is especially valuable in urban areas where real estate is costly.

Operational Accuracy

The combination of automated shuttle vehicles and WMS software reduces human error in picking and inventory management. Barcode or RFID scanning ensures 99.9%+ accuracy, minimizing costly mistakes in order fulfillment.

Labor Optimization

The system requires fewer workers for routine tasks like picking and replenishment, allowing staff to focus on value-added activities such as quality control and customer service. Studies show labor savings of 30-50% in warehouses adopting this technology.

Scalability and Flexibility

Modular design allows for easy expansion as business grows. Additional shuttle vehicles or racking lanes can be added incrementally without disrupting existing operations. The WMS can also integrate with other enterprise systems like ERP and TMS for end-to-end supply chain visibility.

Energy Efficiency

Shuttle vehicles consume less energy than traditional material handling equipment. Their compact size and precise movements reduce unnecessary travel, contributing to a 20-30% lower carbon footprint compared to conventional warehouses.

Diverse Applications Across Industries

- E-Commerce Fulfillment

For online retailers facing high order volumes and short delivery expectations, the shuttle racking system with WMS duo enables rapid order processing. Items can be retrieved and packed in minutes, supporting same-day or next-day delivery services.

- Cold Chain Logistics

In temperature-controlled environments like food and pharmaceutical storage, the system minimizes door openings by consolidating access points. This helps maintain consistent temperatures, reducing energy consumption and preserving product integrity.

- Manufacturing Work-in-Progress (WIP)

Factories use the system to manage components and sub-assemblies between production stages. The WMS can prioritize materials based on production schedules, ensuring just-in-time delivery to assembly lines.

- Third-Party Logistics (3PL) Providers

As a service to multiple clients, 3PL operators benefit from the system’s ability to handle diverse inventory types and SKU volumes. The WMS can allocate storage zones by client, enabling efficient multi-tenant operations.

- Healthcare and Pharmaceutical

In hospitals and pharmacies, the system ensures accurate and quick retrieval of medical supplies and medications. Features like first-expired-first-out (FEFO) management help reduce waste and ensure compliance with regulatory standards.

Shuttle Racking System with WMS is the Future

As global supply chains become more complex and customer expectations rise, businesses must adopt technologies that enhance agility and reliability. The shuttle racking system integrated with WMS addresses these challenges by:

- Enhancing Throughput: Capable of processing hundreds of orders per hour, it keeps pace with growing demand.

- Improving Traceability: Every item movement is recorded, facilitating audits and recalls.

- Enhancing Safety: Reduced human interaction with heavy machinery lowers workplace accidents.

- Supporting Sustainability: Optimized energy use and space efficiency align with environmental goals.

In conclusion, the integration of shuttle racking system with WMS represents a leap forward in warehouse automation. By combining physical efficiency with digital intelligence, this solution empowers businesses to operate smarter, faster, and more sustainably. Whether you’re looking to expand your warehouse capacity or streamline order fulfillment, this technology offers a scalable and future-proof investment for modern logistics operations.