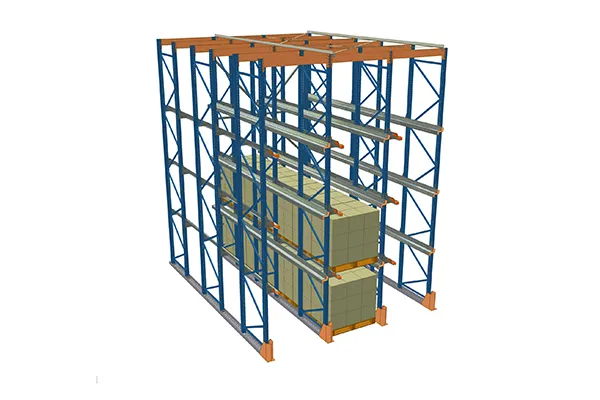

Drive In Pallet Racking Description

As a professional warehousing equipment manufacturer, HUAYIDE Drive In Racking is designed specifically for bulk cargo storage. Its advanced drive-through structure allows for continuous pallet storage, significantly improving warehouse space utilization.

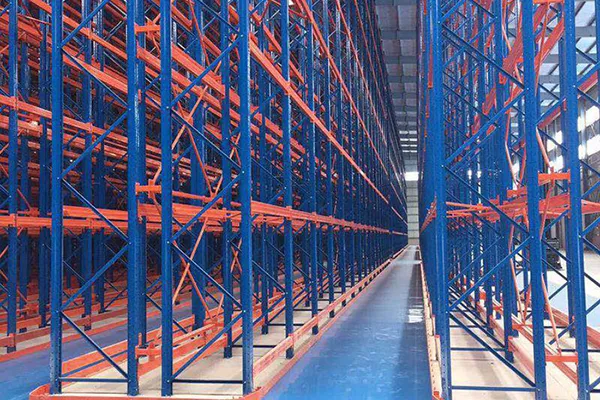

Drive in pallet racking is widely applicable to industries requiring high-volume storage, such as food and cold chain. Its one-way and two-way access design, combined with a heavy-duty column system, ensures both secure storage and first-in, first-out management, making it an ideal choice for modern intelligent warehousing.

Drive In Racking System Applications

- Food and Beverage Industry: Adapts to the large-volume storage needs of standardized packaging. It facilitates centralized management of products of the same specifications and is particularly suitable for fast-moving goods such as bottled beverages and dairy products.

- Cold Chain Logistics Industry: Reduces ineffective space within cold storage and reduces energy consumption from cooling air loss, while maintaining stable low temperatures for stored goods.

- Wholesale and Retail Industry: Supports large-volume stocking during promotional periods, enabling centralized storage and rapid sorting within limited space.

Warehouse Drive In and Drive Through Racking System Detail Display

Drive In Racks Usage Scenarios

Drive Through Racking is designed for high-volume, low-variety goods, enabling first-in, last-out management and improving warehouse space utilization and storage safety.

Drive In Racking eliminates traditional aisles, allowing forklifts to access and retrieve goods directly, ensuring stable loads and high-density storage. Drive in racking offers a lower overall investment cost, saving businesses long-term operating expenses.

Its robustness and support for first-in, last-out management help businesses improve storage efficiency in space-constrained environments.