Introduction

Pallet Racking is the indispensable framework upon which modern warehouse operations are built. In an era defined by supply chain volatility and escalating real estate costs, a well-planned racking system transforms chaotic storage into a model of order and accessibility. For distributors seeking reliable, high-margin products to offer, and for end-users aiming to slash operational costs and boost throughput, understanding the depth and breadth of contemporary pallet racking solutions is crucial. This guide illuminates how the right racking strategy, coupled with seamless integration and expert partnership, can unlock unprecedented levels of storage efficiency and operational resilience.

Pallet Racking: Core Classifications and Strengths

Not all storage challenges are alike, and neither are pallet racking systems. Selecting the appropriate type is the first critical decision, directly impacting density, accessibility, and handling costs.

- Universal Pallet Racking: This is the most widely adopted system, offering direct, individual access to every single pallet in the system. Its open design creates clear aisles for forklifts or other handling equipment.

- Key Features & Advantages: Provides 100% selectivity, ideal for First-In-First-Out (FIFO) inventory management, which is essential for perishable goods or items with expiration dates. Its modular design allows for easy reconfiguration and height adjustment as needs evolve. It offers excellent compatibility with a vast range of products and pallet sizes.

- Best For: Warehouses with a high SKU count, fast-moving inventory, or where every pallet needs to be immediately accessible without moving others.

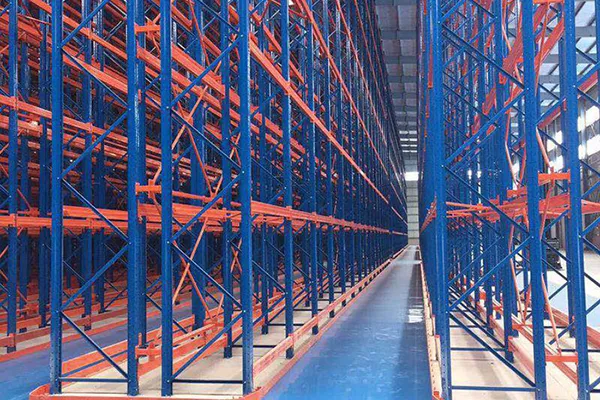

- Drive-In/Drive-Through Racking: This system sacrifices some accessibility for significantly higher storage density. Forklifts drive directly into the rack structure to place or retrieve pallets, which are stored on rails in multiple rows deep.

- Key Features & Advantages: Dramatically increases storage capacity by minimizing aisle space. Ideal for Last-In-First-Out (LIFO) or batch storage of homogeneous products.

- Best For: Storing large quantities of the same product, such as beverages in a distribution center or raw materials in manufacturing.

- Mobile Pallet Racking: An evolution from static racks, this system mounts rack rows on motorized mobile bases that move along floor rails. Only one or two aisles are required for the entire warehouse, as aisles are created on demand.

- Key Features & Advantages: Can increase storage capacity by up to 80% compared to static selective racking. Enhances security and environmental control by compacting storage when not in use.

- Best For: Archives, cold storage facilities, or any application where space is at an absolute premium and inventory turnover is managed in batches.

- Pallet Rack and Stacker Crane ASRS: A Pallet Rack and Stacker Crane ASRS integration forms the backbone of a high-density, fully automated unit-load warehouse, where the rack provides the structured storage space and the computer-controlled crane executes precise, hands-off storage and retrieval operations.

- Key Features & Advantages: This combination delivers unparalleled space utilization through narrow-aisle design, ensures total inventory control and accuracy via integrated Warehouse Management Software (WMS), and dramatically boosts operational efficiency while reducing labor costs and safety risks.

- Best For: It is ideally suited for manufacturing plants, distribution centers, and cold storage facilities that require high-throughput, automated handling of large volumes of standardized palletized goods, from raw materials to finished products.

Integrating Pallet Racking with Advanced Warehouse Technologies

A modern pallet racking system rarely operates in isolation. Its true potential is unlocked when integrated with other material handling equipment, forming a cohesive and intelligent ecosystem.

- Integration with Stacker Crane ASRS (Automated Storage and Retrieval Systems): Selective and drive-in racking provides the structural framework for automated stacker cranes. The precise dimensions and load-bearing requirements of the racking are critical inputs for ASRS design, ensuring smooth and reliable crane operation within the aisles. This combination is paramount for high-bay warehouses seeking ultra-high density and fully automated goods-to-person retrieval.

- Integration with Shuttle Systems: Mobile racking or specially designed static racking forms the dense storage lanes for autonomous shuttle cars. The racking provides the guided rails upon which shuttles travel to store and retrieve pallets deep within the system. This semi-automated solution offers a excellent balance of high density and improved throughput compared to fully manual systems.

- Compatibility with Material Handling Equipment: The fundamental design of pallet racking, particularly selective racks, ensures compatibility with a wide array of handling equipment. This includes:

- Counterbalance Forklifts: The standard for wide-aisle applications.

- Reach Trucks: Essential for operating in the narrower aisles of high-density selective racking layouts.

- Order Pickers: Used for manual picking from rack faces in distribution centers.

- Electric Stackers: Ideal for lower-level handling and loading in facilities with mezzanine structures.

Industry Applications: Tailored Advantages Across Sectors

The versatility of pallet racking solutions allows them to deliver targeted benefits across diverse industries, addressing unique operational pain points.

- Manufacturing & Automotive:

- Challenge: Storing heavy, often bulky components like engines, transmissions, and metal sheets with strict traceability and just-in-time delivery requirements.

- Our Solution: Heavy-duty selective racking or cantilever systems, fabricated from high-strength steel like Q235B with capacities exceeding 3000kg per level. Advantages include robust organization of work-in-progress inventory, support for FIFO to manage batch numbers, and compatibility with large forklifts, ensuring seamless integration into production lines.

- Food & Beverage and Cold Chain Logistics:

- Challenge: Maintaining stringent hygiene standards, managing high volumes of perishable goods with FIFO discipline, and operating efficiently in energy-intensive cold environments.

- Our Solution: Corrosion-resistant racking with appropriate finishes. Selective racking is ideal for enforcing strict FIFO rotation. Mobile racking can significantly reduce the refrigerated volume needed, leading to substantial energy savings in cold storage facilities. The systems facilitate efficient inspection and rotation of stock.

- E-commerce & Retail Distribution:

- Challenge: Extremely high SKU counts, rapid inventory turnover, seasonal demand spikes, and the need for fast, accurate order picking.

- Our Solution: Highly flexible and reconfigurable selective pallet racking. It allows for dynamic slotting strategies, efficient use of vertical space in distribution centers, and direct access for both bulk replenishment and piece-picking operations. This setup maximizes pick faces and speeds up order fulfillment cycles.

- Third-Party Logistics (3PL) and General Warehousing:

- Challenge: Needing extreme flexibility to handle diverse client products with varying sizes, weights, and storage durations, all while maximizing the utility of leased space.

- Our Solution: Modular selective racking systems are the perfect fit. Their adaptability allows a 3PL to quickly reconfigure storage layouts for different clients. The system’s efficiency and 100% accessibility make it a universally applicable and cost-effective backbone for any multi-client warehouse.

Our Comprehensive Service Framework

We deliver more than just high-quality pallet racking components; we provide a holistic partnership that guarantees a successful outcome from conception to long-term operation.

- Consultative Design and Engineering: Our process begins with a thorough audit of your needs—analyzing SKU data, load profiles, handling equipment, and growth plans. We use advanced design software to create optimized layout plans and load calculations, ensuring safety and efficiency are engineered into the system from the start.

- Custom Manufacturing and Quality Assurance: We fabricate racks using high-strength, roll-formed steel profiles and apply durable powder coatings for long-term protection against wear and corrosion. Every beam and upright undergoes rigorous quality checks. We offer customization in dimensions, load capacities, and special finishes (e.g., for cold storage) to meet exact specifications.

- Streamlined Logistics and On-Time Delivery: We manage the entire supply chain, from production scheduling to delivery. Components are clearly labeled and packaged for efficient staging and just-in-time delivery to your site, minimizing on-site clutter and installation time.

- Professional Installation and Safety Certification: Our certified installation teams ensure precise and safe assembly according to all engineering specifications and local safety regulations (e.g., OSHA, SEMA). We conduct final load tests and provide a comprehensive safety certification upon project completion.

- Ongoing Support and Maintenance Programs: Our partnership continues after installation. We offer preventive maintenance inspections, spare parts programs, and retrofit services to adapt your racking system as your business evolves. Our experts are available for safety audits and operational efficiency reviews.

Conclusion: Building a Future-Proof Storage Foundation

Investing in a pallet racking solution is an investment in the foundational efficiency and scalability of your entire logistics operation. By choosing a system that aligns with your specific operational model, integrates seamlessly with your chosen technology, and is backed by a partner committed to your long-term success, you build more than a warehouse—you build a competitive advantage. Let us help you engineer a storage environment that is not only robust and reliable today but also agile enough to meet the demands of tomorrow.

Discover how our tailored pallet racking solutions can transform your storage space into a strategic asset. Contact our expert team for a complimentary warehouse assessment and system design proposal.