Introduction: Redefining Safety in Hazardous Material Storage

An Automated Explosion-Proof Warehouse is no longer a luxury for forward-thinking companies in high-risk sectors—it is an imperative strategic investment for sustainable growth. In industries such as chemicals, pharmaceuticals, oil & gas, paints, coatings, aerospace, and specialty manufacturing, the storage and handling of flammable substances present constant challenges. Traditional manual warehouses in these environments are fraught with risks: human error, potential for static discharge, friction sparks, and the unavoidable presence of personnel in hazardous zones. The consequences of an incident are severe, ranging from catastrophic asset loss and prolonged downtime to irreparable harm to your brand reputation and, most importantly, human safety.

This is where a purpose-built, automated explosion-proof storage and retrieval solution transforms the paradigm. It represents a holistic approach to material handling that seamlessly integrates unparalleled safety protocols with groundbreaking operational efficiency. By removing personnel from high-risk areas and implementing intrinsically safe automation, you are not just mitigating risk; you are unlocking new levels of productivity, accuracy, and scalability. This article explores why an explosion-proof AS/RS (Automated Storage and Retrieval System) is the cornerstone of a modern, resilient, and competitive industrial operation.

Why Your Hazardous Operations Demand an Explosion-Proof Automated Solution

Businesses storing flammable liquids, gases, powders, or components face a unique set of logistical and safety hurdles that conventional warehouses exacerbate:

- Inherent Safety Risks: Constant threat of fire or explosion due to vapors, dust clouds, or accidental ignition sources.

- Stringent Regulatory Compliance: Navigating complex and ever-tightening global standards (ATEX in Europe, NEC in North America, IECEx internationally) is mandatory and challenging.

- Operational Inefficiency: Manual handling in bulky personal protective equipment (PPE) is slow, labor-intensive, and limits throughput.

- Inventory Inaccuracy: Manual tracking in hazardous zones leads to errors, causing production delays or safety issues from material misplacement.

- High Insurance and Liability Costs: Elevated risk profiles result in exorbitant insurance premiums and potential liability exposures.

- Skilled Labor Shortages: Finding and retaining personnel willing and trained to work in such demanding environments is increasingly difficult.

An automated warehouse for hazardous materials is engineered from the ground up to address these exact pain points, turning vulnerabilities into controlled, optimized processes.

Tangible Benefits of Implementing an Explosion-Proof Automated Warehouse

Investing in a dedicated hazard-proof automated warehouse solution delivers profound and measurable returns across your entire organization:

- Uncompromising Personnel Safety: The core benefit. By fully automating storage and retrieval tasks, personnel are removed from high-risk zones. This eliminates the potential for human-error-related incidents and exposure to hazardous atmospheres.

- Guaranteed Regulatory Adherence: Our systems are designed and certified to comply with ATEX, NEC, and other international explosion-protection directives, providing peace of mind and simplifying audit processes.

- Dramatically Enhanced Operational Efficiency: Automated cranes and shuttles operate 24/7 with precision and speed, far exceeding manual capabilities. This leads to higher throughput, faster order fulfillment, and optimized warehouse cube utilization.

- Pinpoint Inventory Accuracy & Traceability: Every container, pallet, or tote is tracked in real-time via integrated Warehouse Management Software (WMS). You gain complete visibility, flawless FIFO (First-In, First-Out) control, and full lot/batch traceability—critical for quality control and recalls.

- Significant Cost Reduction: Lower insurance premiums due to reduced risk, decreased labor costs, minimized product loss from damage or misplacement, and optimized energy use in controlled environments all contribute to a compelling ROI.

- Business Continuity & Risk Mitigation: Protecting your valuable inventory and production inputs from catastrophic loss ensures supply chain resilience and safeguards your market position.

- Environmental Responsibility: Reduced product waste, optimized energy consumption for climate control, and safer containment of materials contribute to more sustainable operations.

- Future-Proof Scalability: Modular design allows the explosion-proof automated storage system to grow seamlessly with your business, accommodating new product lines or increased volumes without major redesigns.

Core Components of Our Integrated Explosion-Proof Warehouse Solution

-

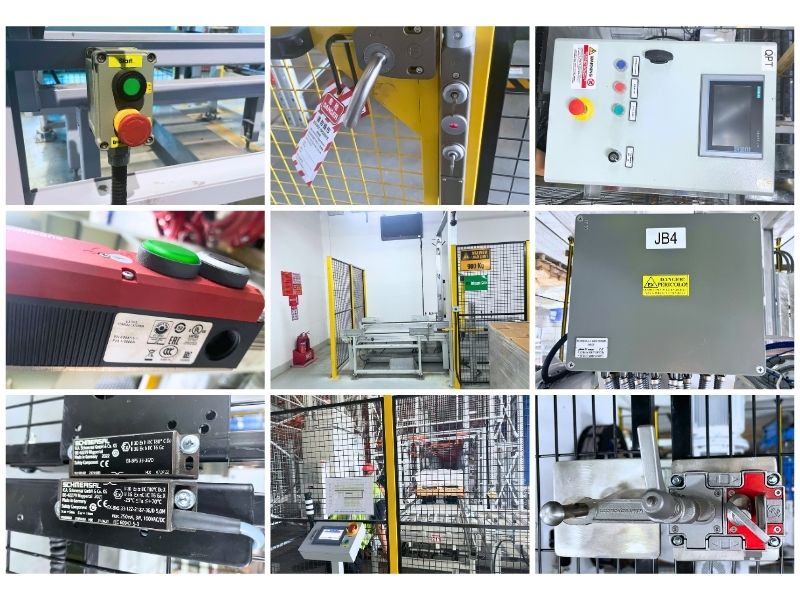

Intrinsically Safe Automation Hardware

The physical backbone of the system is built with safety as the primary design criterion:

- Explosion-Proof Stacker Cranes & Shuttles: The heart of the system. These are equipped with motors, drives, controls, and sensors housed in pressurized or encapsulated enclosures to prevent ignition. Options include:

- Single-mast or double-mast stacker cranes for high-bay pallet handling.

- High-speed mini-load shuttles for handling smaller containers or totes.

- Robotic palletizers/depalletizers integrated within the safe zone.

- ATEX-Compliant Conveyor Systems: Specially designed conveyors with protected bearings, non-sparking materials, and proper grounding to safely transport materials into and out of the storage aisles.

- Protected Warehouse Structure: The entire storage area, including racking, can be designed as a contained, ventilated, or classified zone to manage atmosphere and contain any potential incident.

-

Advanced Safety & Control Systems

Intelligence and prevention are layered into every operation:

- Continuous Atmosphere Monitoring: Sensors constantly check for concentrations of flammable gases, vapors, or dust. The system can be programmed to trigger alarms, increase ventilation, or safely shut down operations if thresholds are approached.

- Intrinsically Safe Electrical Design: All wiring, connections, and components within the hazardous area are rated for the specific zone classification, eliminating potential electrical ignition sources.

- Redundant Safety Controls: Multiple fail-safe mechanisms, including emergency stop circuits, anti-collision sensors, and overload protection, ensure safe operation under all conditions.

- Fire Suppression Integration: The system can be seamlessly integrated with specialized fire suppression systems (e.g., foam, inert gas) that are automatically activated in case of a fire, designed to extinguish it without damaging the automation equipment.

-

Intelligent Software Suite

The “brain” that orchestrates safety, efficiency, and insight:

- Specialized Explosion-Proof WMS/WCS: A Warehouse Management and Control System tailored for hazardous environments. It manages:

- Real-time, 3D Inventory Tracking: Know the exact location and status of every item.

- Compliance-Driven Putaway & Picking: Automatically enforces safety rules (e.g., chemical segregation, temperature limits) and optimizes storage for both safety and efficiency.

- Comprehensive Audit Trail: Automatically logs all material movements, system access, and alarm events for full regulatory reporting.

- Digital Twin & Simulation: Allows for pre-commissioning testing and ongoing optimization of workflows in a virtual, risk-free environment.

- Predictive Analytics & Maintenance: Monitors equipment health to predict maintenance needs before failures occur, preventing downtime and potential safety issues.

Tailored Solutions for Your Industry

Our automated warehouse solution for explosive atmospheres is not one-size-fits-all. We engineer systems specific to your sector’s needs:

- Chemical & Petrochemical: Handling drums, intermediate bulk containers (IBCs), and raw materials. Focus on vapor control, chemical compatibility, and high throughput.

- Pharmaceutical & Fine Chemicals: Storing flammable solvents and active pharmaceutical ingredients (APIs). Requires ultra-clean (cleanroom-compatible) designs and meticulous traceability.

- Paints, Coatings & Inks: Managing large volumes of flammable liquids and aerosols. Solutions often include automated dispensing and mixing station integration.

- Aerospace & Defense: Storing composite resins, fuels, and propellants. Demands extreme precision, security, and compliance with military specifications.

- Food & Beverage (High-Risk Areas): For facilities using alcohol-based flavors or operating spray-dryers creating combustible dust (e.g., milk powder, starch).

Your Roadmap to a Safer, Smarter Warehouse

Implementing an automated explosion-proof storage system is a strategic partnership. Our proven process ensures success:

- Comprehensive Hazard Analysis & Consulting: Our experts work with you to classify zones, identify risks, and define precise requirements.

- Customized Solution Design: We engineer a system that fits your specific footprint, throughput goals, product mix, and compliance landscape.

- Seamless Integration & Project Management: We handle the entire process—from civil works to software integration—with minimal disruption to your ongoing operations.

- Certification & Commissioning: We ensure the complete system meets all necessary certifications before handover.

- Lifelong Support & Optimization: We provide continuous remote monitoring, maintenance, and software updates to keep your system at peak performance.

Conclusion: Build Your Foundation for the Future

In an era where safety, efficiency, and resilience are non-negotiable, clinging to outdated manual methods in hazardous storage is a significant liability. An Automated Explosion-Proof Warehouse is the definitive solution to this challenge. It represents a proactive investment that pays dividends not only in risk mitigation and cost savings but also in creating a robust, scalable, and intelligent operational backbone.

Don’t let the limitations of your current storage infrastructure cap your growth or expose you to unnecessary danger. Embrace the technology that sets the new standard for industrial safety and productivity.

HUAYIDE is your trusted partner in this critical transformation. We bring the engineering excellence, industry expertise, and unwavering commitment to safety required to deliver your complete hazardous material automated warehouse solution. Contact us today for a confidential consultation and let us build your shield for the future.