In the rapidly evolving landscape of modern logistics and warehousing, the Pallet Lift stands out as a pivotal innovation, revolutionizing how businesses handle inventory management and material flow. This sophisticated component of automated storage and retrieval systems (ASRS) is designed to elevate operations to new heights of efficiency, safety, and scalability. As industries grapple with increasing demands for speed and precision, the Pallet Lift emerges as a critical solution, seamlessly integrating into complex warehouse ecosystems to optimize space utilization and workflow automation.

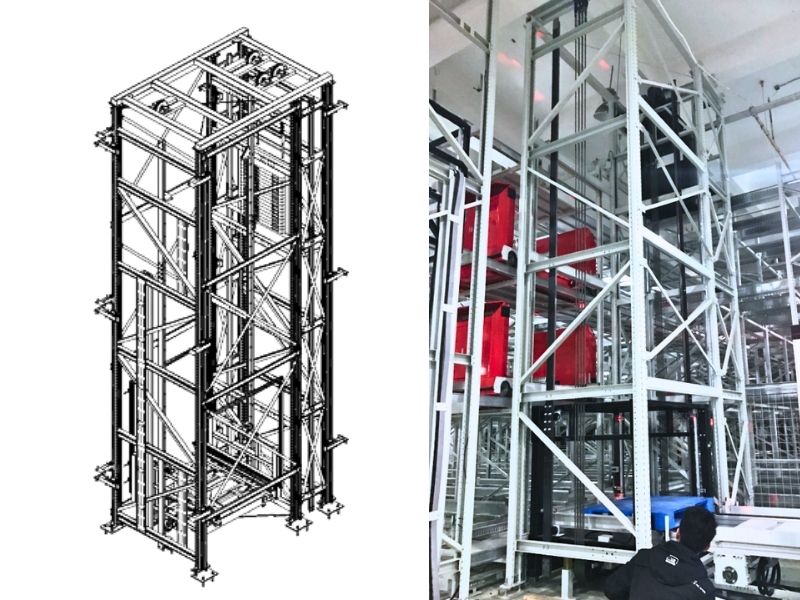

Core Components of the Pallet Lift System

The Pallet Lift is not a standalone entity but a intricate assembly of meticulously engineered parts, each playing a vital role in its seamless operation:

- Lifting Mechanism: At the heart of the system lies the vertical movement apparatus, typically powered by electric motors or hydraulic cylinders. This component enables precise elevation and lowering of palletized loads, ensuring smooth transitions between storage levels.

- Carriage Unit: The pallet-bearing platform that travels along vertical guides, designed to securely hold loads during ascent and descent. Modern carriages feature advanced locking mechanisms to prevent load shifting.

- Guiding Rails: Precision-engineered vertical tracks that ensure straight-line movement with minimal vibration, maintaining load stability throughout the vertical journey.

- Control System: The intelligent brain of the operation, comprising sensors, actuators, and programmable logic controllers (PLC) that manage movement sequences, speed regulation, and safety protocols.

- Safety Features: Multiple layers of protection including emergency stop buttons, load limit sensors, obstruction detection, and fail-safe braking systems to prevent accidents.

- Interface Components: Input/output devices for operator interaction and integration with broader warehouse management systems (WMS).

Classifications of Pallet Lift Systems

Pallet Lift technology offers diverse configurations tailored to specific operational requirements:

- Single Pallet vs. Dual Pallet Lifts: Standard models handle one pallet at a time, while advanced dual pallet versions simultaneously manage two loads, doubling throughput capacity.

- Low-Level vs. High-Level Lifts: Categorized by their vertical reach, with low-level lifts typically serving ground-level storage and high-level units accessing mezzanine floors or multi-tier racking systems.

- Throughput-Oriented vs. Storage-Oriented Models: Throughput-focused systems prioritize rapid vertical movement for high-velocity operations, while storage-oriented units emphasize precise positioning for dense inventory accumulation.

- Hybrid Integrated Systems: These combine vertical lifting with horizontal transfer capabilities, creating fully automated storage solutions that minimize human intervention.

Operational Applications Across Industries

The versatility of Pallet Lift technology makes it indispensable across diverse industrial sectors:

- Food and Beverage Industry: For managing temperature-controlled storage environments where hygiene and speed are paramount.

- Pharmaceutical Manufacturing: In secure, regulated environments requiring precise inventory tracking and audit trails.

- Automotive Parts Distribution: Handling heavy components in just-in-time production systems where space optimization is critical.

- E-Commerce Fulfillment Centers: For high-speed order picking operations in massive distribution warehouses.

- Airport Ground Handling: In baggage sorting and cargo storage systems where space is at a premium.

- Third-Party Logistics (3PL) Providers: Offering scalable storage solutions for multi-client operations with diverse inventory profiles.

Defining Characteristics of Modern Pallet Lifts

Contemporary Pallet Lift systems incorporate several innovative features:

- Space-Efficient Design: Their vertical orientation minimizes horizontal footprint, allowing warehouses to utilize cubic space more effectively.

- Precision Positioning Technology: Advanced sensors and servo controls enable millimeter-level accuracy in pallet placement.

- Modular Scalability: Systems can be expanded vertically or horizontally to accommodate growing storage needs without major infrastructure changes.

- Energy-Efficient Operation: Regenerative braking systems and low-power standby modes contribute to sustainable warehouse operations.

- Intelligent Load Handling: Capacitive sensors and AI-powered vision systems can detect load characteristics and adjust handling parameters accordingly.

- Seamless Integration Capabilities: Designed to work in harmony with other material handling equipment through standard communication protocols.

Competitive Advantages in Modern Warehousing

Implementing Pallet Lift technology delivers measurable benefits:

- Enhanced Operational Efficiency: By automating vertical transport, Pallet Lifts significantly reduce cycle times compared to manual handling methods.

- Improved Workplace Safety: Eliminating the need for workers to operate at height or handle heavy loads reduces workplace injuries and符合 compliance requirements.

- Optimized Inventory Management: Precise positioning capabilities enable better stock rotation and inventory control.

- Increased Storage Capacity: Vertical space utilization allows warehouses to store more inventory without expanding floor space.

- Reduced Labor Costs: Automation of vertical transport functions decreases reliance on manual labor for repetitive tasks.

- Superior Traceability: Integrated tracking systems provide real-time data on inventory movement and location.

- Enhanced Material Flow: Smooth integration with conveyor systems and other material handling equipment creates uninterrupted production lines.

- Future-Proof Design: Modular architecture allows for technology upgrades without complete system replacement.

- Improved ergonomics: By eliminating strenuous vertical lifting tasks, Pallet Lifts contribute to better employee well-being and productivity.

Industry-Specific Benefits

Different sectors experience unique advantages from Pallet Lift implementation:

- Retail Distribution Centers: Benefit from improved order fulfillment speed and accuracy during peak seasons.

- Cold Storage Facilities: Maintain temperature-controlled environments more effectively with minimized door openings.

- Heavy Manufacturing: Handle large, bulky components with greater ease and precision.

- High-Tech Electronics: Provide cleanroom-compatible handling solutions for sensitive components.

- Automotive Assembly: Enable just-in-time delivery of parts to production lines with clockwork precision.

- Fashion and Apparel: Facilitate organized storage of seasonal inventory with quick accessibility.

- Book and Media Distribution: Offer efficient handling of high-volume, low-weight products.

- Medical Supplies: Ensure secure storage and retrieval of sensitive healthcare products.

The Pallet Lift Advantage in Action

Consider a typical distribution center scenario: Without Pallet Lift technology, workers might spend hours manually transporting pallets between different storage levels using forklifts or stair climbers. This approach is not only time-consuming but also poses safety risks and limits storage density.

By contrast, an integrated Pallet Lift system can:

- Reduce vertical transport time by up to 75%

- Increase storage capacity by 40-60% through better vertical space utilization

- Improve inventory accuracy to near 100% through automated tracking

- Cut labor costs by eliminating dedicated vertical transport personnel

- Enhance workplace safety by removing workers from hazardous lifting operations

Future Outlook and Innovations

As warehouse automation continues to evolve, Pallet Lift technology is poised for exciting advancements:

- AI-Powered Predictive Maintenance: Using machine learning algorithms to anticipate maintenance needs before failures occur.

- Autonomous Mobile Integration: Seamless operation with autonomous mobile robots (AMRs) for end-to-end material handling solutions.

- Green Energy Solutions: Adoption of solar-powered charging stations and energy-efficient components.

- Augmented Reality Interfaces: For enhanced operator training and troubleshooting capabilities.

- Blockchain Integration: For enhanced security and traceability in sensitive supply chains.

Conclusion

In conclusion, the Pallet Lift represents a transformative leap forward in material handling technology. By addressing the vertical dimension of warehouse operations, these systems unlock unprecedented levels of efficiency, safety, and scalability. As businesses across industries continue to seek competitive advantages through operational excellence, the Pallet Lift stands ready as a cornerstone technology for the warehouses of the future.