Automated Storage and Retrieval System (ASRS) represents one of the most transformative technologies in modern logistics and supply chain management. In an era defined by the relentless pursuit of efficiency, accuracy, and speed, these sophisticated robotic systems have emerged as the intelligent backbone of warehouses, distribution centers, and manufacturing plants worldwide. They are not merely machines replacing manual labor; they are complex, integrated solutions that redefine the very nature of inventory management. By seamlessly blending advanced hardware with intelligent software, ASRS solutions are unlocking unprecedented levels of operational productivity, setting new standards for what is possible in the world of material handling.

Core Functions

At its heart, an ASRS is designed to perform a set of fundamental tasks that form the core of any storage operation. Its primary mission is to automate the processes of storing and retrieving items from defined storage locations with minimal human intervention.

- Automated Storage: Upon receiving goods, the system automatically determines the optimal storage location based on predefined rules such as size, weight, turnover rate (using FIFO or LIFO principles), and stock-keeping unit (SKU) velocity. The item is then transported and placed into the assigned bin, rack, or shelf.

- High-Speed Retrieval: When an order is received, the system’s software directs the robotic mechanism to precisely retrieve the required item from its location and deliver it to a designated workstation for picking, packing, or directly to a shipping area.

- Real-Time Inventory Control: These systems are integrated with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software, providing a real-time, accurate view of all inventory. This eliminates manual stock counts and the errors associated with them.

- Sortation and Consolidation: Advanced ASRS can also sort items for outbound shipping or consolidate products from different zones for completing multi-item orders efficiently.

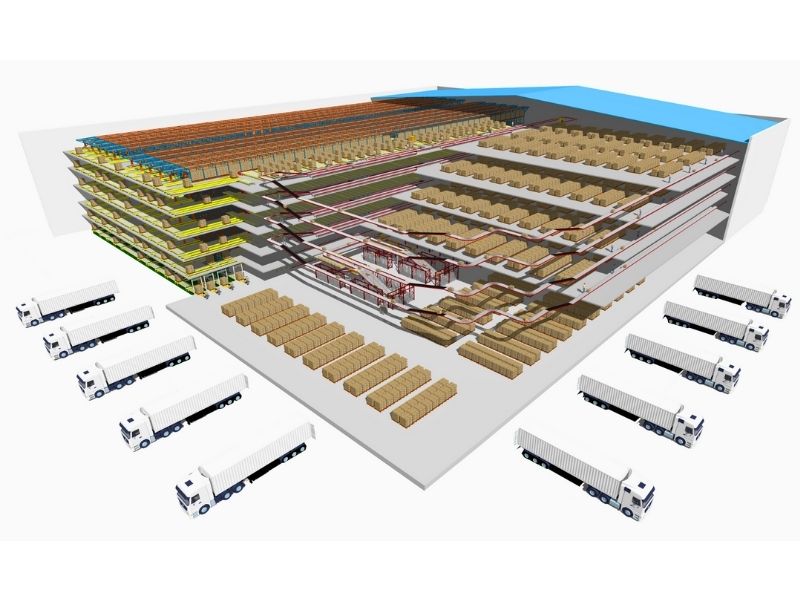

Architectural Composition: The Trinity of Hardware, Software, and Control

A fully functional Automated Storage and Retrieval System is a symphony of three critical components working in perfect harmony.

- The Hardware Framework: This is the physical structure and machinery. It includes the storage structure itself (often high-rise racking), the robotic delivery mechanisms (such as cranes, shuttles, or robotic carts), and Conveyor systems (conveyors, lifts, and transfer cars) that connect the ASRS to other parts of the facility.

- The Central Intelligence: Software Suite: The software is the brain of the operation. It typically consists of a specialized control system that manages the hardware, integrated with a WMS. This software layer handles tasks like inventory management, transaction processing, order prioritization, and route optimization for the robotic machinery.

- The Sensory Network: Control System: This includes the programmable logic controllers (PLCs), sensors, scanners, and communication networks that translate the software’s commands into precise physical actions. They ensure the cranes and shuttles move accurately, confirm pick and place operations, and maintain overall system safety.

Distinctive Features and Overwhelming Advantages

The adoption of an Automated Storage and Retrieval System brings a host of compelling advantages over traditional manual warehousing.

- Maximized Spatial Utilization: By utilizing vertical space with high-density storage racking, ASRS dramatically increases storage capacity within the same or even a smaller building footprint.

- Unmatched Accuracy and Traceability: Barcode scanners and RFID technology integrated into the system ensure virtually error-free transactions, leading to perfect order fulfillment rates and complete item traceability from receiving to dispatch.

- Dramatic Labor Optimization: These systems significantly reduce the reliance on manual labor for repetitive and physically demanding tasks, allowing the human workforce to be redeployed to higher-value activities like quality control and process management.

- Enhanced Workplace Safety: By automating tasks that involve heavy lifting and operation of forklifts in narrow aisles, ASRS create a much safer working environment, substantially reducing the risk of accidents and product damage.

- Superior Throughput and Scalability: Robotic systems can operate 24/7, leading to a massive increase in the speed and volume of orders processed. Furthermore, the systems are modular and can be scaled to meet growing business demands.

- Improved Stock Integrity: Precise environmental control and reduced human handling help preserve the quality of sensitive products, which is crucial for industries like pharmaceuticals and food and beverage.

A Spectrum of System Classifications

The term “ASRS” encompasses a diverse family of systems, each engineered for specific types of inventory and operational needs.

- Unit-Load ASRS: Designed for handling very large and heavy palletized loads. These systems often feature massive aisle-changing cranes and are used for storing raw materials or finished goods in bulk.

- Mini-Load ASRS: Tailored for handling smaller loads stored in totes or bins. The crane or shuttle operates within a narrow aisle to store and retrieve individual containers, making it ideal for order fulfillment and kitting operations.

- Vertical Lift Modules (VLMs) and Horizontal Carousels: These are space-saving systems where trays or bins are delivered to an ergonomic workstation. VLMs operate vertically, while carousels rotate horizontally, both presenting items directly to the operator.

- Autonomous Mobile Robots (AMRs) with Storage: This newer category utilizes fleets of collaborative mobile robots that can transport entire shelving units to workers, effectively bringing the shelves to the person, a concept known as “goods-to-person.”

Pervasive Applications Across Modern Industries

The versatility of Automated Storage and Retrieval System technology has led to its widespread adoption across a multitude of sectors.

- E-commerce and Retail Fulfillment: This is a primary driver of ASRS adoption, where the technology is critical for managing vast SKU counts and meeting expectations for fast, accurate, and same-day shipping.

- Cold Storage Logistics: In freezer and refrigerated environments, Automated Storage and Retrieval System solutions minimize the time personnel need to spend in harsh conditions while ensuring the integrity of temperature-sensitive goods.

- Aerospace and Automotive Manufacturing: These industries use robust unit-load and mini-load systems to manage large, expensive components and parts with high precision, supporting just-in-time manufacturing lines.

- Healthcare and Pharmaceuticals: VLMs and mini-load ASRS are extensively used in hospitals for managing medical supplies and in pharmaceutical warehouses where strict regulatory compliance, lot tracking, and environmental control are non-negotiable.

- Food and Beverage: The systems ensure efficient handling while maintaining strict hygiene standards and enforcing First-In-First-Out (FIFO) inventory management to prevent spoilage.

Conclusion

In conclusion, from its core components to its diverse applications, the impact of Automated Storage and Retrieval System (ASRS) technology is profound and far-reaching. It is no longer a luxury for a few but is rapidly becoming a necessity for any business seeking to build a resilient, responsive, and competitive supply chain for the future.