Understanding Pallet Racking Systems

Pallet racking represents a fundamental material handling infrastructure designed specifically for storing materials on pallets in warehouses, distribution centers, and manufacturing facilities. These structural frameworks enable efficient storage of unit loads while ensuring easy accessibility through various handling equipment. Unlike solid shelving units, pallet racking systems utilize open configurations that maximize vertical space utilization while maintaining excellent visibility and air circulation throughout the storage area.

The fundamental purpose of pallet racking extends beyond simple storage—it transforms unused vertical space into productive inventory capacity while establishing systematic organization that streamlines inventory management processes. By implementing appropriate racking solutions, businesses can achieve optimal density storage configurations that directly translate to reduced operational costs and enhanced workflow efficiency.

Core Structural Components and Manufacturing process

Vertical Upright Frames

The vertical components, commonly referred to as upright frames, form the backbone of any pallet racking system. These steel structures feature precisely punched openings at regular intervals along their height, allowing for adjustable beam placement. The robust column design incorporates specific structural reinforcements at critical stress points to withstand both static and dynamic loads throughout the system’s operational life. Modern manufacturing employs high-strength steel that undergoes rigorous cold-forming processes, followed by protective coating applications that resist corrosion in various environmental conditions.

Horizontal Load Beams

Connecting the upright frames horizontally, load beams provide the direct support surface for palletized goods. These components feature specially engineered end connectors that securely lock into the upright frame openings without requiring additional tools for adjustment. The beam design incorporates a trapezoidal profile that maximizes strength-to-weight ratio while maintaining a relatively lightweight structure. Manufacturers typically produce these elements using roll-formed steel sections that undergo stress testing to verify load capacity specifications.

Additional Structural Elements

Complete pallet racking installations incorporate several supplementary components that enhance safety and functionality. These include wire mesh decking that provides secure pallet support while allowing sprinkler system water penetration, row spacers that maintain proper alignment between back-to-back rack configurations, frame braces that increase structural stability through diagonal cross-members, safety pins that prevent accidental beam dislodgement, and column protectors that shield upright frames from impact damage.

Primary Classification of Pallet Racking Systems

Selective Pallet Racking

As the most widely implemented storage solution, selective racking offers direct access to every pallet position within the system. This configuration maintains individual aisle spaces between rack rows, providing unimpeded access to all stored materials. The design philosophy prioritizes accessibility over storage density, making it ideal for facilities handling high-SKU inventories with frequent rotation requirements. Operations utilizing standard forklift equipment typically find selective racking the most practical solution for balanced throughput and storage capacity.

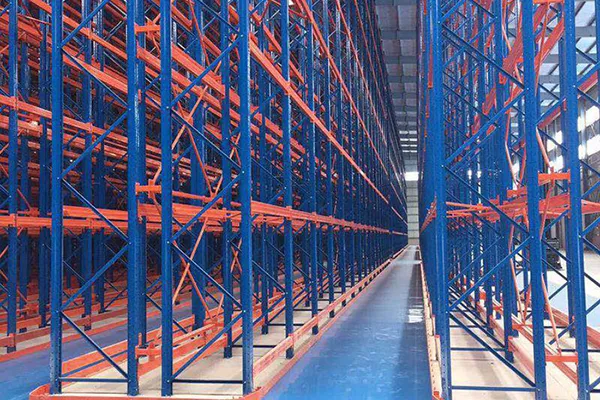

Drive-In/Drive-Through Racking

Engineered for high-density storage of homogeneous products, drive-in systems utilize a series of connected rack structures where forklifts operate within the rack framework itself. This configuration eliminates dedicated access aisles between individual pallet positions, significantly increasing storage density. Drive-in systems feature entry from one side only, while drive-through configurations allow access from both ends. These solutions prove particularly valuable for cold storage applications and high-volume inventory with first-in-first-out or last-in-first-out rotation requirements.

Push-Back Racking

Incorporating dynamic storage principles, push-back systems utilize wheeled carts positioned on inclined rails within each storage bay. This design allows pallets to be stored multiple deep while maintaining selective access capabilities. When a forklift operator retrieves the front pallet, subsequent loads automatically gravitate forward to the accessible position. The system typically supports multiple pallet depths, offering an optimal balance between selectivity and storage density for medium-turnover products.

Leveraging gravity-assisted movement, flow systems incorporate roller conveyors mounted on a slight decline within each storage lane. Loaded pallets enter from the elevated loading end and gradually flow toward the unloading position at the opposite end. This automated first-in-first-out inventory rotation proves invaluable for time-sensitive products with explicit expiration considerations. The continuous movement mechanism reduces product handling time while ensuring perfect stock rotation without manual intervention.

Distinctive Characteristics and Operational Advantages

Modular Flexibility and Scalability

Pallet racking systems exemplify modular design principles, allowing configurations to evolve alongside changing storage requirements. The adjustable nature of beam levels facilitates accommodation of varying product heights within the same system. Expansion possibilities enable seamless integration of additional units as storage needs grow, protecting initial infrastructure investments while supporting business development.

Optimized Space Utilization

By capitalizing on previously unused vertical air space, racking installations dramatically increase storage capacity within existing facility footprints. Properly engineered systems can safely extend to near-ceiling heights, potentially multiplying available storage positions compared to floor-level storage approaches. This vertical expansion strategy delays the need for costly facility expansions or relocations.

Enhanced Operational Safety

Structured racking systems promote warehouse safety through multiple mechanisms. The organized storage approach eliminates unstable pallet stacking while clearly defining traffic aisles and storage zones. Integrated safety features including load locks and column guards protect both inventory and personnel from accidents. Properly configured systems also improve sprinkler system effectiveness and facilitate compliance with fire safety regulations.

Improved Inventory Management

The systematic organization inherent in racking installations enables logical inventory arrangement according to usage frequency, product category, or other operational parameters. This structured approach reduces item retrieval times while minimizing selection errors. The physical organization complements digital inventory management systems, creating synergistic efficiency gains throughout the supply chain.

Load Capacity Considerations and Engineering Principles

Understanding load capacity represents a critical aspect of pallet racking selection and configuration. System capacity depends on multiple interdependent factors including upright frame specifications, beam ratings, and overall configuration design. Engineering calculations must account for both uniformly distributed loads and concentrated point loads that occur during normal operations.

Structural integrity relies on proper weight distribution across all supporting elements. Heavier loads should typically occupy lower positions within the rack structure, maintaining a low center of gravity that enhances stability. Modern rack design incorporates sophisticated safety factors that accommodate unexpected stress variations while maintaining structural reliability. Professional engineers should always verify that proposed configurations comply with relevant regional standards and seismic requirements where applicable.

Regular inspections should verify that actual loads remain within designated capacity ratings while checking for any structural compromises resulting from accidental impacts or environmental factors. Progressive warehouses implement periodic inspection protocols to document loading conditions and identify potential concerns before they escalate into serious safety issues.

Application Scenarios Across Industries

Retail Distribution Centers

Large-scale distribution operations servicing retail chains utilize sophisticated racking configurations to manage immense product varieties. These facilities typically combine selective racking for broken-case picking with high-density systems for full-pallet reserve storage. The flexibility of modern racking solutions accommodates dramatic seasonal inventory fluctuations characteristic of the retail sector.

Manufacturing and Raw Material Storage

Production facilities employ racking systems to organize raw materials, work-in-progress components, and finished goods. The systematic storage approach supports just-in-time manufacturing principles while minimizing production disruptions caused by material shortages. Custom configurations often accommodate non-standard load sizes and specialized handling requirements.

Cold Storage Facilities

Temperature-controlled environments present unique challenges that racking systems specifically address. Corrosion-resistant coatings protect components from moisture damage while open designs promote crucial air circulation around stored products. High-density configurations maximize valuable refrigerated space, directly reducing energy consumption per stored pallet.

Third-Party Logistics Providers

The diverse client requirements handled by 3PL operations demand exceptionally adaptable storage solutions. Modular racking systems enable configuration adjustments to accommodate various product types, turnover rates, and special handling requirements across multiple client accounts within the same facility.

Future Developments and Technological Integration

The evolution of pallet racking continues to align with broader trends in warehouse automation and digitalization. Emerging innovations include integrated sensor technology for monitoring load distribution and detecting structural stresses, robotic compatibility modifications facilitating seamless interaction with automated retrieval systems, advanced composite elements offering enhanced strength with reduced weight, and sophisticated configurator software that optimizes system layouts based on specific operational parameters.

These advancements promise continued improvements in storage efficiency, operational safety, and management visibility while maintaining the fundamental principles that make pallet racking indispensable to modern supply chains.

Conclusion

Pallet racking systems form the foundational infrastructure enabling efficient modern logistics operations. Their versatile designs, adaptable configurations, and proven reliability make them invaluable assets across countless industrial and commercial applications. By understanding the various system types, their appropriate applications, and proper implementation principles, businesses can significantly enhance their storage capabilities while improving overall operational efficiency. As supply chain demands continue evolving, pallet racking technology will undoubtedly advance accordingly, maintaining its critical role in global commerce and material handling.