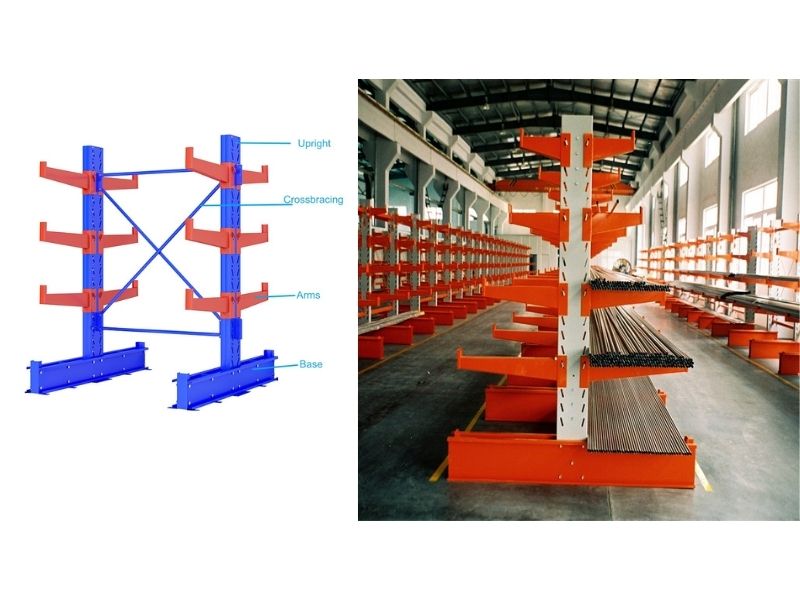

In modern warehouse architecture, cantilever racking systems have emerged as the gold standard for storing lengthy, bulky, or irregularly shaped inventory. Characterized by their column-free design with horizontal arms projecting from vertical support structures, these systems – sometimes referred to as arm-type shelving or beam-and-column racks – provide unmatched accessibility for items exceeding standard pallet dimensions.

Functional Architecture of Cantilever Racking

Structural Intelligence

Unlike conventional shelving, cantilever racks utilize a cantilever principle where loads are supported at fixed points while leaving the front completely unobstructed. Key operational features include:

- Modular arm configurations permitting adjustable spacing (typically 200-400mm increments)

- Bi-directional load distribution through reinforced base plates and diagonal bracing

- Hybrid capacity options ranging from light-duty (300kg/arm) to heavy-industrial (8,000kg/arm) variants

Operational Versatility

The open-front design of pallet-compatible cantilever racks enables:

- Simultaneous loading/unloading from multiple access points

- Compatibility with various material handling equipment (forklifts, cranes, or manual carts)

- Dynamic reconfiguration without structural modifications

Engineering Specifications Breakdown

Material science plays a pivotal role in cantilever rack performance:

- Structural steel composition: ASTM A36 or DIN EN 10025 S355JR grades dominate the market

- Protective treatments: 80-100μm hot-dip galvanization ensures corrosion resistance in humid environments

- Seismic resilience: Moment-resistant connections in high-risk zones (e.g., California or Japan installations)

Cross-Industry Deployment Case Studies

Construction Material Logistics

A Scandinavian timber supplier achieved 37% space optimization by implementing double-sided cantilever racks with 3m arms for 12-meter lumber storage. The system’s boltless design allowed seasonal adaptation for plywood sheets during winter months.

Aerospace Component Management

Boeing’s South Carolina facility utilizes galvanized cantilever structures with RFID-enabled arms to track wing spars, reducing retrieval time by 52% compared to traditional floor stacking.

Retail Supply Chain Innovation

Home Depot’s Midwest distribution center employs hybrid cantilever/pallet rack systems for seasonal garden equipment, demonstrating the technology’s scalability for mixed-load warehouses.

Competitive Differentiation

When benchmarked against alternative storage systems, cantilever racking demonstrates measurable superiority:

Versus Drive-In Racks

- 60% faster inventory turnover due to direct access

- 40% lower maintenance costs (no guide rail damage from forklifts)

Versus Mobile Shelving

- 300% higher weight capacity per square meter

- No electrical dependency for operation

Versus Block Stacking

- 80% reduction in product damage claims

- 25° safety angle prevents toppling of cylindrical loads

The Next Frontier: Smart Cantilever Technologies

Emerging innovations are transforming conventional cantilever racks into intelligent storage ecosystems:

- Predictive load sensors: Strain gauges monitor arm deflection in real-time

- Automated position systems: Motorized arms align with AGV pickup points

- Sustainable designs: Recycled steel alloys with carbon footprint tracking

Application Scenarios of Cantilever Racking

Cantilever racking is widely adopted across multiple industries due to its adaptability and robust design. It caters to environments where standard shelving falls short, particularly in handling items that require horizontal support and unobstructed access. Below, we delve into the primary industries that benefit from this storage solution.

Manufacturing and Industrial Sector

In manufacturing plants, cantilever racking is indispensable for storing raw materials and unfinished goods. For instance, in metal fabrication workshops, it efficiently holds steel beams, pipes, and sheets. The open design allows workers to easily load and unload materials using cranes or forklifts, streamlining production workflows. Similarly, in woodworking industries, these racks organize lumber and panel products, reducing clutter and minimizing damage during handling.

Warehousing and Logistics

Warehouses specializing in long or oversized items rely heavily on cantilever racking to optimize space. In logistics hubs, they store items like furniture, construction materials, and automotive parts. The ability to adjust arm heights and lengths enables customization for seasonal inventory fluctuations, such as storing gardening tools in spring or holiday decorations in winter. This flexibility supports just-in-time inventory management, enhancing overall supply chain efficiency.

Retail and Wholesale Distribution

In retail and wholesale settings, cantilever racking is used for bulk storage of goods that are difficult to stack on standard shelves. For example, home improvement stores utilize these racks for plumbing supplies, PVC pipes, and molding trims. The visible, accessible layout facilitates quick stock checks and restocking, improving customer service and reducing operational delays.

Products Suitable for Cantilever Racking

The versatility of cantilever racking lies in its ability to accommodate a wide range of products, particularly those with unique dimensions or shapes. Here, we categorize and exemplify the common items stored using this system.

Long and Linear Items

These include products that require continuous support along their length to prevent bending or damage. Examples comprise:

- Construction Materials: Rebar, lumber, and aluminum extrusions, which are essential in building projects and need secure, organized storage to maintain integrity.

- Metal and Plastic Pipes: Used in plumbing and irrigation, these items can be stacked horizontally on cantilever arms without risk of rolling or deformation.

Bulky and Irregularly Shaped Goods

Cantilever racking excels in storing non-uniform items that do not fit neatly into standard bins or shelves. Notable examples are:

- Furniture and Fixtures: Table tops, cabinets, and door frames, which benefit from the open access for inspection and retrieval without disassembling entire stacks.

- Automotive Parts: Exhaust pipes, bumper beams, and roll cages, often stored in repair shops or distribution centers to support efficient inventory turnover.

Specialized Industrial Components

In niche sectors, cantilever racks handle specialized products that demand precise handling. For instance:

- Aerospace Components: Wing spars and fuselage sections, which require high-load capacity and stability to ensure safety and compliance with industry standards.

- Textile Rolls: Large fabric bolts in manufacturing, where the racking system prevents unraveling and allows for easy color or material selection.

Advantages of Cantilever Racking in Various Industries

Implementing cantilever racking offers numerous benefits that translate into operational efficiency and cost savings. Below, we outline the key advantages tailored to specific applications and product types.

Enhanced Space Utilization and Accessibility:

The design of cantilever racking eliminates front columns, providing clear aisles for loading and unloading. In the manufacturing sector, this means faster access to raw materials, reducing downtime and increasing productivity. For example, in a metalworking facility, workers can swiftly retrieve steel pipes using overhead cranes, minimizing handling time and boosting output. Additionally, the adjustable arms allow for dense storage configurations, maximizing vertical space in warehouses and reducing the need for expansive floor areas.

Improved Product Protection and Safety:

By supporting items horizontally, cantilever racking prevents bending, warping, or crushing that can occur in stacked piles. In retail environments, this ensures that products like PVC pipes remain undamaged, maintaining quality and reducing waste. Moreover, the sturdy construction and even weight distribution enhance stability, lowering the risk of accidents such as collapses. In industries like aerospace, where components are high-value and sensitive, this safety aspect is crucial for compliance and risk management.

Flexibility and Scalability for Dynamic Needs:

Cantilever systems are highly customizable, with arms that can be repositioned to accommodate changing inventory sizes. In logistics, this adaptability supports seasonal shifts, such as storing skis and snowboards in winter or pool equipment in summer, without requiring structural modifications. This scalability also future-proofs investments, as businesses can reconfigure racks rather than replace them, leading to long-term cost savings and sustainability.

Cost-Effectiveness and Operational Efficiency:

The efficiency gains from cantilever racking directly impact the bottom line. In wholesale distribution, for instance, quicker restocking and retrieval times reduce labor costs and improve order fulfillment rates. The durability of materials like heavy-gauge steel also minimizes maintenance needs, extending the system’s lifespan. Overall, these factors contribute to a faster return on investment, making cantilever racking a smart choice for industries focused on growth and optimization.

Conclusion

In summary, cantilever racking is a vital storage solution that addresses the unique challenges of handling long, bulky, or irregular products across diverse industries. Its applications in manufacturing, warehousing, and retail demonstrate its versatility, while its ability to store items like construction materials and automotive parts highlights its practicality. The advantages—ranging from space efficiency and product safety to flexibility and cost savings—make it an indispensable asset for modern businesses. As industries continue to evolve, cantilever racking will remain a key enabler of streamlined operations and enhanced productivity.