Smart Shuttle Racking Systems

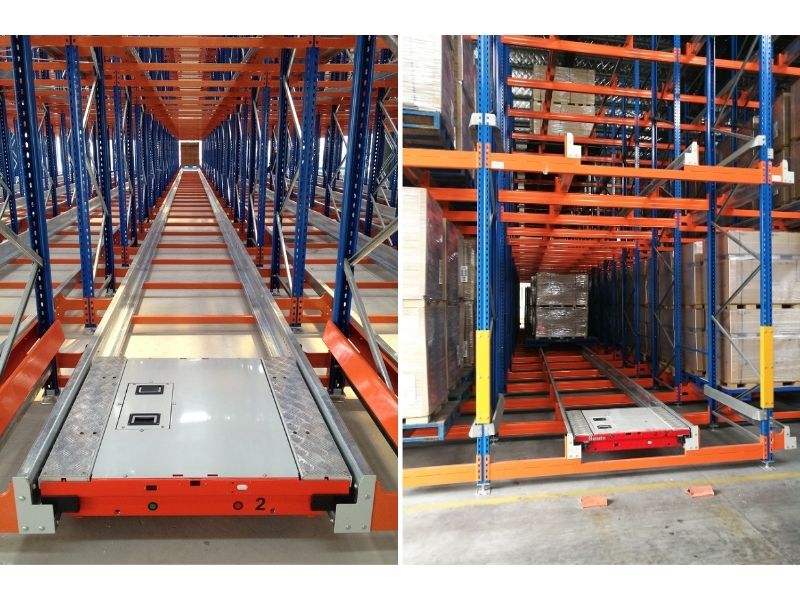

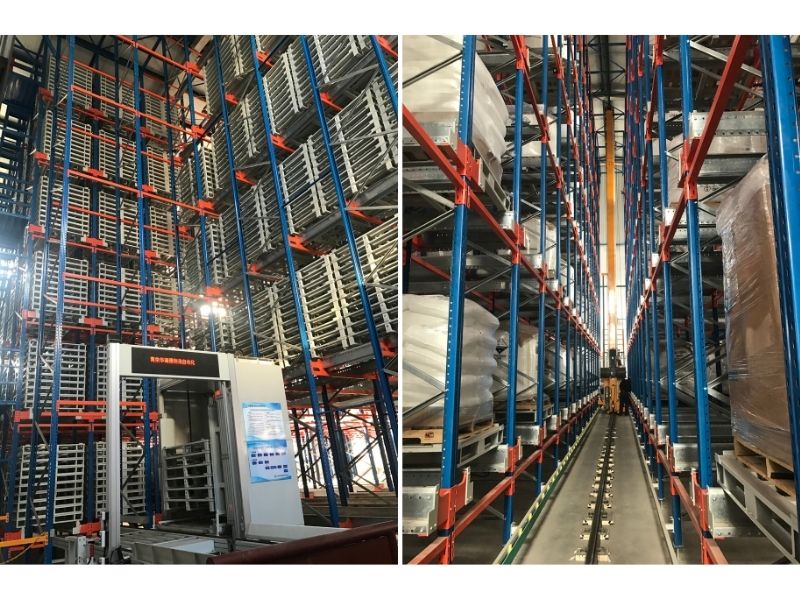

Automated shuttle racking represents the next evolution in warehouse automation. Unlike conventional pallet racking that relies on forklifts, this system uses computer-controlled shuttle vehicles that travel along fixed rails within storage lanes. Each shuttle operates independently with battery power, capable of lifting, moving, and placing pallets with millimeter precision.

The core components include:

- Rail-mounted shuttles with lifting mechanisms

- Central control software for task coordination

- Modular racking structures with adjustable depths

- Sensor arrays for real-time inventory tracking

This architecture transforms static storage into a dynamic, three-dimensional logistics network where goods flow vertically and horizontally as needed.

Key Advantages Over Traditional Systems

- Operational Efficiency Leap

Shuttle systems eliminate human walking time between pick locations. During peak seasons at a European distribution center, operators reported:

- 300% faster order fulfillment

- 90% fewer walking errors

- Continuous operation during shift changes

- Space Optimization

The high-density storage design:

- Reduces aisle requirements by 60%

- Allows 12-meter deep storage lanes

- Enables mezzanine-level installations

- Labor Cost Transformation

One control station can manage multiple shuttels, significantly reducing dependency on manual labor.

- Scalability

Additional shuttles can be deployed without infrastructure changes, supporting business growth.

Industry-Specific Adaptations

- Cold Storage: Specialized shuttles operate in -25°C environments

- Pharmaceuticals: Integrated batch tracking meets FDA requirements

- E-commerce: Fast-moving SKUs receive priority lanes

Smart Warehouse Integration

When connected to WMS, the system enables:

- Live inventory visualization

- Predictive maintenance alerts

- Energy consumption optimization

Implementation Considerations

Successful adoption requires:

- Proper racking structure design

- Power supply redundancy

- Staff training programs

The Future of Automated Storage

Emerging technologies like AI-powered shuttle swarms and self-charging systems promise even greater efficiency gains. As supply chains grow more complex, shuttle systems provide the agility needed to handle fluctuating demand patterns.