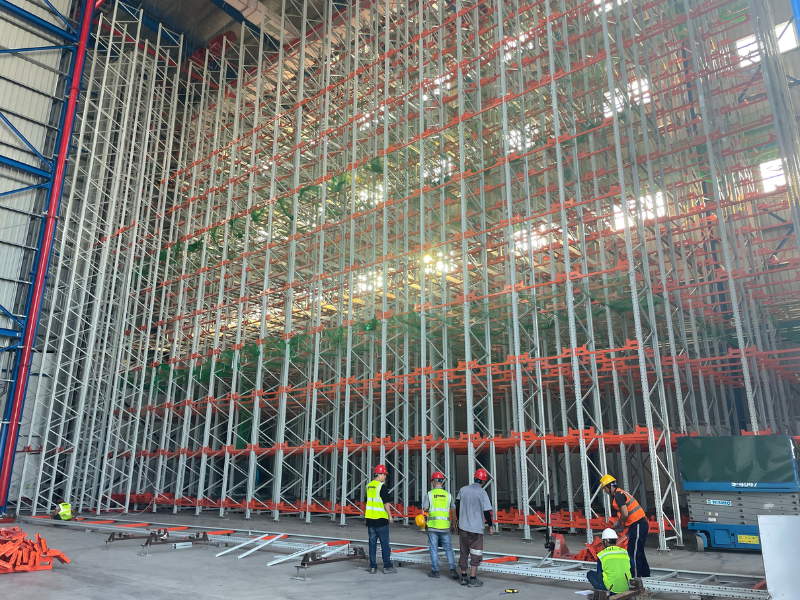

The Four Way Shuttle Racking System is a high-density, highly intelligent automated warehousing solution. It consists of three-dimensional racks, intelligent shuttles that can move horizontally and vertically, elevators, and an intelligent control system.

Core Equipment Introduction

- Shuttle: Crafted from lightweight alloy, it features dual laser and QR code positioning systems and a hydraulic lift mechanism, enabling 24/7 continuous operation.

- Lift: Enables cross-level shuttle scheduling and facilitates vertical movement.

- Conveyor System: Assists with the racking system for transport and retrieval.

Workflow

- Task Allocation: The WMS generates the optimal route, and the WCS dispatches the shuttle to execute the task.

- Cargo Storage and Retrieval: The shuttle precisely places the cargo using a pallet lift, then returns to standby or perform a new task.

- Cross-Level Operation: The lift transports the shuttle to the target floor, where it then moves horizontally to the designated cargo location.

Core Features of Four Way Shuttle Racking System

The pallet shuttle is equipped with a four-wheel independent motor drive system. It can move forward, backward, and horizontally on the rack rails, and can be raised and lowered via a lift, enabling precise positioning and retrieval of goods in three dimensions.

This racking system eliminates the need for forklift access. The racking layout is highly compact, improving storage space utilization. An algorithm enables multiple shuttles to operate simultaneously.

Advantages and Disadvantages

The four way shuttle warehouse zero-aisle design significantly improves warehouse space utilization. It supports multi-vehicle collaborative operations, increasing efficiency by over three times compared to traditional models. It offers exceptional flexibility, allowing for free horizontal and vertical movement. It can adapt to irregular warehouse layouts and is compatible with a variety of vehicles and specialized environments. Its high degree of automation reduces manual intervention, and its intelligent collision avoidance system ensures safe operation.

Equipment operation is subject to extreme temperatures, which can impact stability. The initial investment and maintenance costs are high, and it relies heavily on professional technical support. Therefore, it requires a manufacturer with dedicated technical engineers and on-site technical guidance.