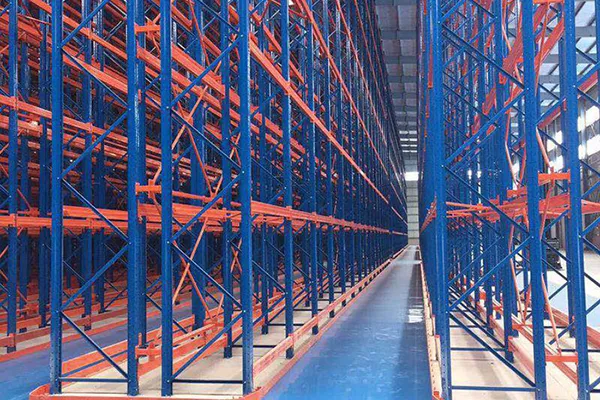

HUAYIDE Gravity Flow Racking system is designed for efficient warehousing. Its inclined tracks and roller structure enable automated cargo sliding, ensuring first-in, first-out management and significantly reducing the need for manual intervention. It’s suitable for high-turnover scenarios such as cold chain, e-commerce, and manufacturing, helping customers optimize space utilization and operational processes.

As a manufacturer, we focus on the pain points of large logistics companies and factories, addressing the low storage and retrieval efficiency and space waste associated with traditional racking. Our steady-flow racking, with its non-powered design, balances storage density and flow efficiency, helping customers build a smart warehousing foundation.

Our clients include logistics service providers, manufacturing companies, and retail distribution centers. We provide customized solutions to ensure our racking systems are fully integrated with our customers’ specific business operations, achieving continuous optimization of warehousing costs and efficiency.

Features of Gravity Flow Pallet Racks

Gravity pallet Flow Racking utilizes an inclined track design. It utilizes its own weight to automatically slide goods, perfectly supporting first-in, first-out warehouse management requirements. Its non-powered operation reduces energy consumption while ensuring efficient goods flow.

This racking system is particularly suitable for high-turnover scenarios such as cold chain and manufacturing industries. By optimizing storage density, it significantly improves space utilization while reducing manual handling, delivering lasting operational benefits to customers.