Features of Pallet Conveyor System

The Automated Pallet conveying System uses intelligent scheduling to achieve automatic conveying, precise positioning, and flexible sorting of palletized materials, seamlessly integrating with AGVs and high-bay warehouses.

HUAYIDE Pallet conveying System features a modular design, multi-load adaptability, intelligent obstacle avoidance, and remote monitoring, adapting to the needs of diverse industrial scenarios. Utilizing the latest collaborative control technology, it ensures smooth and reliable operation, making it a key piece of equipment in the logistics sector of intelligent manufacturing.

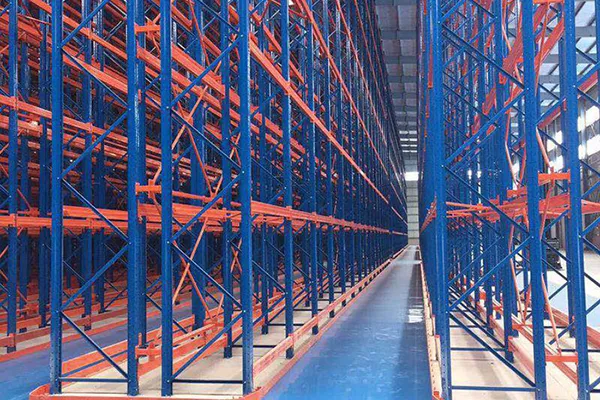

Empower Your Material Flow with Robust Pallet Conveyor Systems

As an industry-leading manufacturer, we specialize in engineering and producing high-performance pallet conveyor solutions that form the backbone of modern intralogistics. Our vertical integration—from design to assembly—ensures every system delivers the reliability and efficiency demanded by today’s dynamic supply chains.

- Manufacturer-Controlled Precision: Every pallet conveyor we build is crafted in our state-of-the-art production facilities. By overseeing the entire manufacturing process, we guarantee superior weld integrity, precise alignment, and consistent quality that meets the highest industry standards.

- Engineered for Demanding Environments: Our pallet conveyor systems are constructed from heavy-duty materials and components, designed to withstand continuous operation under substantial loads. Direct manufacturing allows us to implement rigorous stress-testing and durability validation, ensuring long-term performance with minimal maintenance.

- Modular and Adaptable Configurations: Whether you require straight-line transport, accumulation, or sorting capabilities, our pallet conveyor platform offers inherent flexibility. As the OEM, we can customize dimensions, speeds, and control interfaces to integrate seamlessly into your existing or planned workflow.

- Direct Partnership Advantage: Working directly with us—the manufacturer of the pallet conveyor—eliminates unnecessary intermediaries. This translates to faster response times, transparent technical collaboration, and cost-effective solutions tailored precisely to your operational goals.

Invest in conveyor technology built with the expertise and accountability only a true manufacturer can provide. Let’s streamline your operations together.