Features of Stacker Crane & Shuttle Pallet Racking System

Modular equipment collaborative operation

●The stacker crane is responsible for vertical and horizontal transportation in the main aisle, and the shuttle handles the deep storage and access of the sub-aisle. The two are seamlessly connected through WMS/WCS intelligent scheduling. The modular design supports flexible addition and subtraction of equipment to adapt to throughput fluctuations.

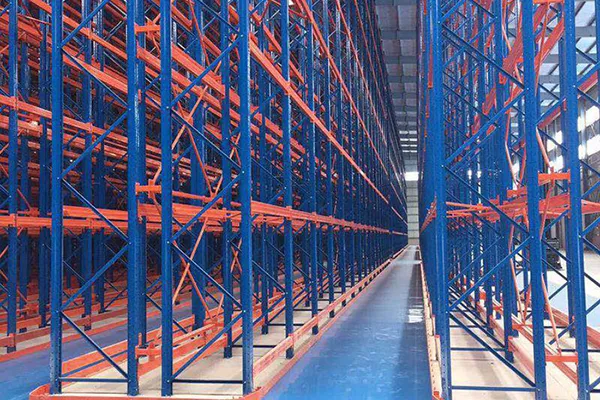

Extreme space utilization

●The racking depth can be expanded to multiple depths, such as double-depth and four-depth. The storage density is 30%-50% higher than that of traditional stacker crane warehouses.

●The narrow aisle design reduces the non-storage area, the vertical height can reach more than 20 meters, and the storage capacity per unit area is doubled.

Efficient and accurate operation capability

●The positioning accuracy of the stacker crane is at the millimeter level, and the shuttle runs at a speed of more than 1.5m/s, which greatly improves the overall storage and access efficiency of the system.

●Supports FIFO and FILO modes to meet the batch management needs of multiple industries such as medicine and food.

Intelligent management closed loop

●The WMS system monitors inventory in real time, and the WCS dynamically optimizes the equipment path with extremely low error rate.

●RFID technology realizes full-process traceability, which is suitable for high-risk scenarios such as cold chain and bonded warehouses.

Cost and safety optimization

●The overall investment cost is 30% lower than the traditional solution, and the manpower requirement is reduced by 70%.

●Multiple safety protections such as anti-collision sensors and emergency stop devices ensure 24-hour stable operation.

Transform Warehouse Operations with Advanced Automated Warehouse with Stacker Cranes

As a premier manufacturer at the forefront of industrial automation, we design and build cutting-edge Automated Warehouse with Stacker Cranes from the ground up. Our integrated manufacturing approach—spanning R&D, production, and testing—ensures these systems deliver unmatched reliability and scalability for your logistics infrastructure.

- End-to-End Manufacturing Control: Every Automated Warehouse with Stacker Cranes unit is engineered and assembled in our state-of-the-art facilities. By owning the entire production chain, we guarantee precision in component fabrication, seamless system integration, and rigorous quality validation for consistent performance.

- Robust and Resilient Engineering: Constructed using premium-grade materials, our Automated Warehouse with Stacker Cranes is built to thrive in high-demand environments. Direct manufacturing oversight enables us to implement exhaustive durability testing, ensuring long-term operational stability with minimal downtime.

- Scalable Architecture for Future Growth: The modular design of the Automated Warehouse with Stacker Cranes allows effortless expansion and reconfiguration. As the OEM, we tailor solutions to your unique space and throughput needs, providing flexibility that evolves with your business.

- Direct Manufacturer Partnership: Collaborating with us—the original source of the Automated Warehouse with Stacker Cranes—eliminates intermediaries. This fosters transparent communication, faster deployment, and cost-efficient access to expert technical support.

Choose the innovation and dependability only a true manufacturer can offer. Let’s elevate your warehouse efficiency together.