Benefits of Mother-child Shuttle Racking System

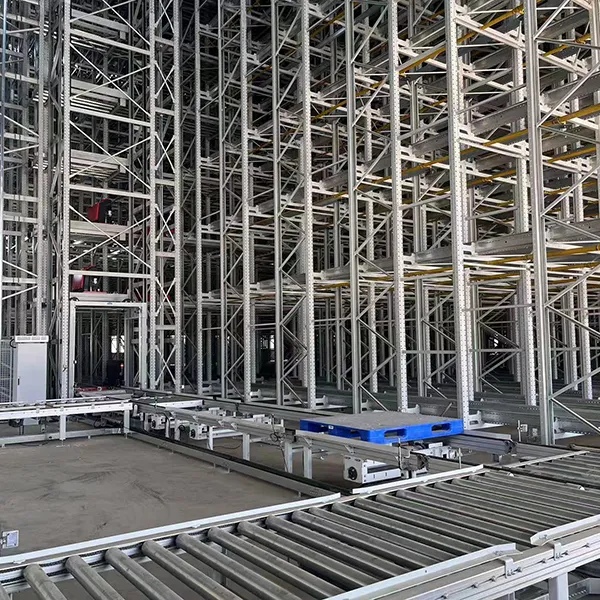

HUAYIDE Mother-child Shuttle System will greatly improve space utilization. Through the double-layer operation mode of mother shuttle cross-aisle transportation link child shuttle two-way storage and retrieval, 50% more storage spaces are added than the traditional shuttle system, which is especially suitable for industrial warehousing scenarios with high land costs.

The intelligent operation efficiency of Mother-child Shuttle System is improved. The WMS system dynamically allocates tasks in real time, and the coordinated scheduling of the mother car and the child car meets the peak demand of e-commerce promotion.

-25℃ to 45℃ full temperature range adaptation. Equipped with low-temperature bearings and anti-condensation circuits, the cold chain version has been applied to pharmaceutical cold storage, and the chemical explosion-proof model has passed ATEX certification.

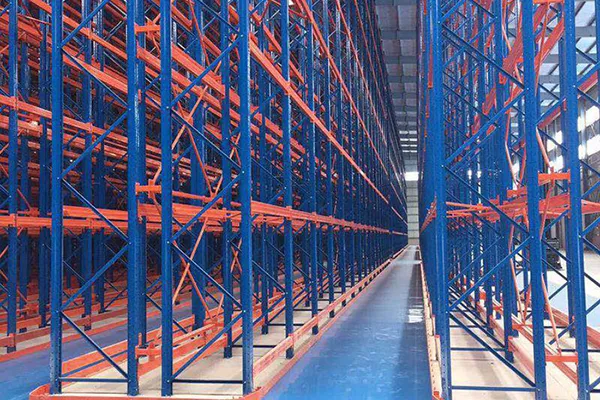

Low transformation cost. Compatible with existing shelf transformation, modular design supports phased implementation, reducing the one-time investment pressure of enterprises.

Intelligent collaborative operation system. Through WMS control, the precise storage and retrieval of the child car and the seamless connection of the mother car cross-aisle transportation are realized.

We verify the layout plan in advance to minimize the risk of project implementation.

Partner With Us to Create the Perfect Mother-Child Shuttle System warehouse

We are proud to present our engineering masterpiece, developed and manufactured in-house with precision and innovation at its core. The Mother Child Shuttle System represents the pinnacle of our manufacturing prowess, designed to redefine efficiency in warehouse automation.

- Engineering Excellence from the Ground Up: As a dedicated manufacturer, we control every aspect of the Mother-Child Shuttle System production. From robust component sourcing to advanced assembly and rigorous testing, our integrated manufacturing process guarantees unparalleled quality and reliability in every unit.

- Scalable and Modular Architecture: The inherent design philosophy of the Mother-Child Shuttle System offers exceptional flexibility. Our manufacturing capabilities allow us to deliver systems that can be seamlessly scaled and configured to meet your specific spatial and throughput requirements, future-proofing your investment.

- Uncompromising Durability and Performance: Built to endure the demands of 24/7 operation, the Mother-Child Shuttle System utilizes high-grade materials and precision engineering. Our direct manufacturing control ensures that every shuttle and rail component meets strict performance benchmarks for speed, accuracy, and longevity.

- Direct Manufacturer Advantage: Partnering with us means partnering directly with the source. This eliminates intermediaries, ensures transparent communication, and provides you with the competitive edge that comes from working with the original equipment manufacturer of the Mother-Child Shuttle System.

Choose the strength and innovation that only a true manufacturer can provide. Let’s build the future of logistics together.