Introduction

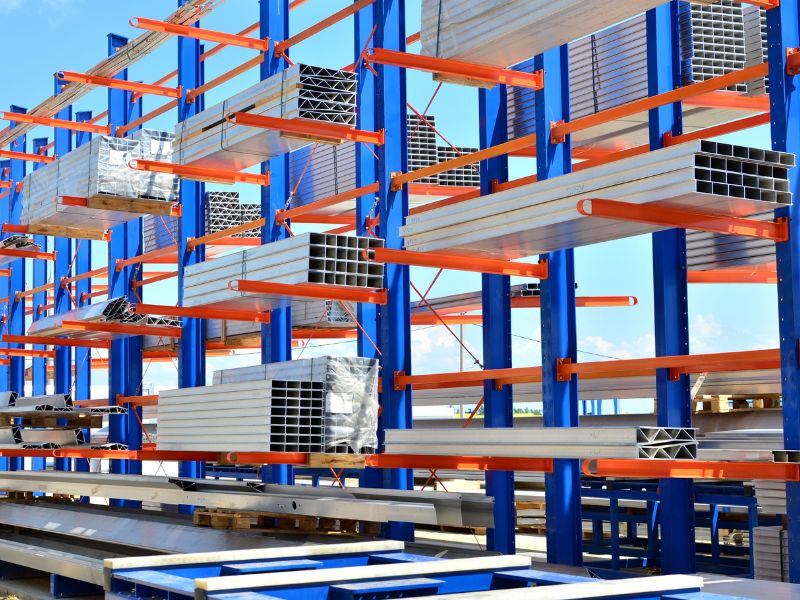

Cantilever Racking is a specialized storage system characterized by its vertical columns and horizontally projecting arms, creating a series of cantilevers upon which goods are placed. Unlike traditional pallet racking, it features a completely open front without vertical uprights, providing unimpeded access along the entire length of the arm. This fundamental design makes it the ideal choice for storing items that are difficult to handle on standard shelving or racks, transforming chaotic storage areas into organized, high-density, and highly accessible inventory zones.

Core Design and Defining Features of Cantilever Racking

Understanding the components and inherent features of cantilever racking is key to appreciating its versatility and strength.

- Robust Structural Components:

- Vertical Columns (Uprights): These are heavy-duty steel columns, typically anchored securely to the floor. They form the backbone of the system, designed to withstand significant vertical and horizontal loads.

- Cantilever Arms: The defining feature, these arms bolt onto the columns and extend outward. They are available in various lengths and capacities to accommodate different load requirements. Arms can be fixed or adjustable in height.

- Base Plates and Anchors: Provide critical stability and ensure the entire racking system is safely secured to the concrete floor, preventing tipping.

- Column Braces and Back Supports: These diagonal or horizontal braces connect columns together in a bay, adding crucial lateral stability and rigidity to the structure, especially for taller systems.

- Key Advantages and Features:

- Unobstructed Front Access: The absence of front uprights allows for the entire length of a long item (like a steel bar or timber plank) to be loaded or unloaded from the side with ease, using forklifts or overhead cranes.

- Exceptional Load Capacity: Engineered from high-grade steel, cantilever racks are built to handle extremely heavy and dense loads on each arm, often ranging from 1,000 to over 10,000 pounds per arm.

- Height and Arm Adjustability: The arms can be repositioned on the column at different heights with minimal effort. This offers incredible flexibility to reconfigure storage space as inventory profiles change over time.

- Durability and Longevity: Hot-rolled steel construction, coupled with high-quality powder-coating or galvanized finishes, ensures resistance to impact, corrosion, and wear, guaranteeing a long service life even in demanding industrial environments.

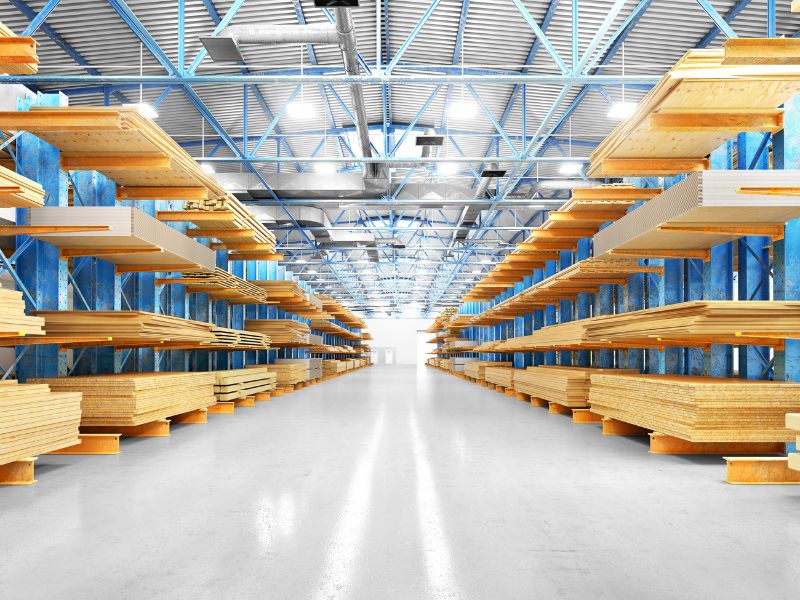

- Space Optimization: By enabling storage of long, bulky items that would otherwise lean against walls or clutter floor space, cantilever systems dramatically increase usable cubic storage volume.

Industry-Specific Applications and Benefits

The practicality of cantilever racking transcends a single industry. Its design solves specific storage challenges across a wide spectrum.

- Metal Service Centers and Fabrication Shops:

- Application: Storing steel bars, tubes, pipes, sheets, and structural beams.

- Specific Advantages: Prevents bending and warping of materials by providing full-length support. Allows for easy visual identification and selective picking of specific lengths or grades, reducing material waste and handling time. Enhances safety by removing the risk of bundles collapsing.

- Lumber and Building Material Suppliers:

- Application: Organizing dimensional lumber, plywood, molding, PVC/acrylic sheets, and rebar.

- Specific Advantages: Keeps wood straight and dry by elevating it off the floor. Facilitates first-in, first-out (FIFO) inventory management. The open design improves air circulation, which is crucial for moisture-sensitive materials.

- Furniture Manufacturing and Warehousing:

- Application: Storing table tops, door slabs, countertops, mattresses, and framed furniture.

- Specific Advantages: Protects finished surfaces from scratches and damage that can occur in stacked piles. Allows for easy access to specific items without moving entire stacks, speeding up order fulfillment for large, fragile goods.

- Automotive and Aerospace Parts Distribution:

- Application: Holding long exhaust pipes, bumper beams, extrusion profiles, and composite materials.

- Specific Advantages: Creates an organized parts library for easy picking. The adjustable arms accommodate a wide variety of part lengths within the same rack bay, maximizing storage density for diverse SKUs.

- Textile and Roll Goods Storage:

- Application: Storing rolls of carpet, vinyl, fabric, foam, and industrial paper.

- Specific Advantages: The cantilever arms act as a spindle, allowing rolls to be stored on their core without flattening. This preserves material quality and makes loading/unloading a simple rolling motion.

- Warehouse and Logistics for Irregular Items:

- Application: Handling awkwardly shaped items such as kayaks, ladders, trim, or special machinery components.

- Specific Advantages: Provides a dedicated, safe location for items that do not fit standard racking, clearing valuable floor space and bringing organization to previously unmanageable inventory.

Our Comprehensive Service Ecosystem

We believe delivering a cantilever racking system is about providing a complete storage solution, not just selling components. Our end-to-end service ensures a perfect fit for your facility and seamless operation.

- Professional Site Survey and Measurement:

- Our specialists visit your facility to take precise measurements of the available space, assess floor conditions, and understand your workflow patterns, traffic aisles, and material handling equipment (e.g., forklift reach heights).

- We identify potential obstacles like columns, sprinklers, or lighting to ensure our design integrates flawlessly with your existing infrastructure.

- Customized Design and Engineering:

- Using advanced CAD and 3D modeling software, we create a detailed layout of the proposed cantilever racking system tailored to your specific inventory dimensions, weights, and access frequency.

- Our engineering team performs structural load calculations to ensure the design meets all relevant safety standards (such as RMI/ANSI MH16.1) and is certified for the intended use.

- We provide clear, annotated drawings and a comprehensive bill of materials for your approval before any manufacturing begins.

- Expert Installation Guidance and Supervision:

- We supply detailed, step-by-step installation manuals and can provide on-site supervision by our technical team during the assembly phase.

- Our experts ensure proper anchoring to the floor, correct alignment of columns and arms, and that all connections are torqued to specification, guaranteeing the structural integrity and safety of the installation.

- We conduct a final inspection and load test to certify the system is ready for safe operation.

- Ongoing After-Sales Support and Maintenance:

- We offer comprehensive training for your staff on the safe loading and unloading procedures for your new cantilever racks.

- Our support includes the availability of spare parts (arms, connectors, etc.) and access to technical advice for future reconfiguration needs.

- We recommend and can provide periodic safety inspections to check for wear, damage, or loosening of components, ensuring your storage system remains in optimal condition for years to come.

Conclusion

Cantilever Racking is more than just metal and bolts; it is a strategic tool for transforming storage challenges into competitive advantages. By providing unmatched accessibility for long and bulky items, it brings order, safety, and density to spaces that were once inefficient. For distributors, offering this solution expands your portfolio into high-value industrial storage. For end users, investing in a professionally designed and supported cantilever system delivers immediate gains in space utilization, operational efficiency, and inventory protection.

Choosing the right partner is critical. Our commitment extends from the initial consultation to the long-term performance of your storage investment. We combine superior cantilever racking products with unparalleled service expertise to deliver a solution that is not only strong and flexible but also perfectly aligned with your unique operational DNA.

Ready to optimize your storage for long, bulky, or irregular items? Contact our storage solutions consultants today for a free, no-obligation site assessment and discover how a custom cantilever racking system can elevate your warehouse organization and productivity.